How to take the zero carbon road of internal combustion engines? The Chief Engineer of Cummins China Advanced Technology said so

Under the trend of energy revolution and low-carbon development, the internal combustion engine industry is facing unprecedented transformation challenges. As a pioneer in global power technology, how has Cummins responded? What are the plans?

Natural gas internal combustion engines can achieve a 15% carbon reduction target, coupled with hybrid technology and optimized thermal efficiency, there is still great growth potential in the future for medium and heavy-duty trucks. At the same time, hydrogen fuel, as a zero carbon solution for internal combustion engines, is already flourishing in the global market

On March 28th, at the 2024 China Commercial Vehicle Forum, Wang Pan, Chief Technology Engineer of Cummins (China) Investment Co., Ltd. (hereinafter referred to as "Cummins") in China, introduced the trend of low-carbon and zero carbon power chain technology for commercial vehicles in his keynote speech.

01

Three Steps to Achieve a Zero Carbon Future

Equivalent to a global truck shutdown of 3 years?

By 2030, Cummins will achieve a 50% carbon reduction target; by 2050, it plans to achieve carbon neutrality. "This is Cummins'" zero carbon "blueprint.

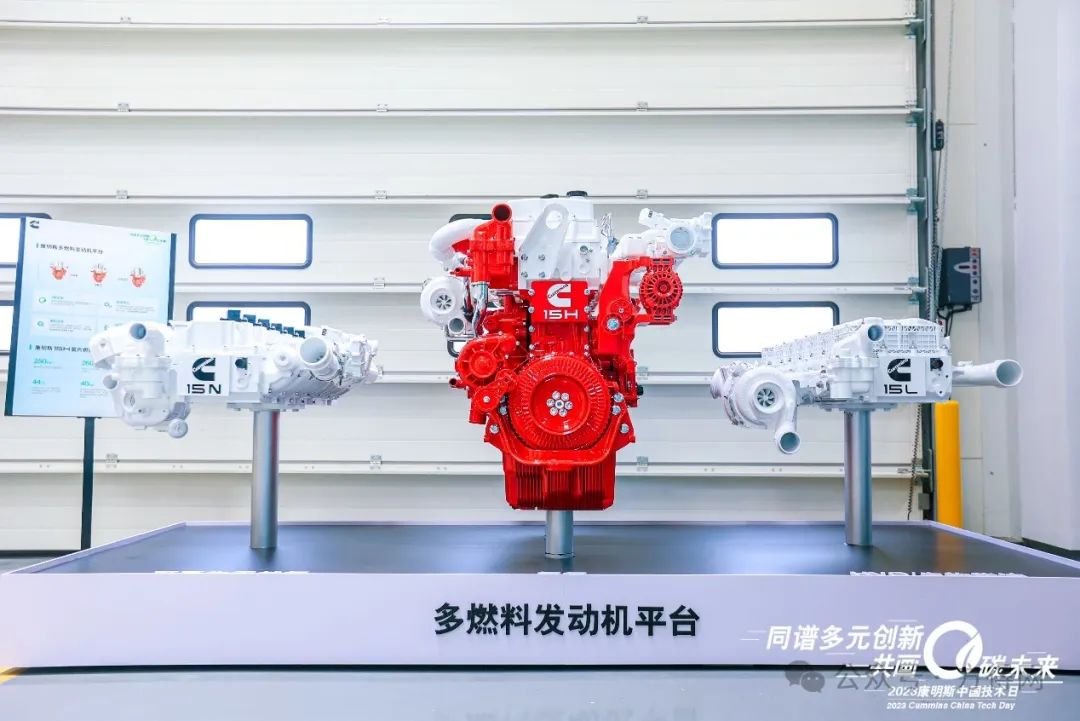

Since proposing the "zero carbon" strategy in 2021, Cummins has planned a multi fuel engine platform. This will not only help the commercial vehicle industry reduce carbon emissions, but also strive to create the best TCO power solution for customers.

Wang Pan stated that Cummins' zero carbon strategy hopes to be implemented in three steps.

The first step is that between 2021 and 2030, Cummins will continuously explore technology to reduce nitrogen oxide and carbon dioxide emissions from internal combustion engines, and promote energy conservation and emission reduction in commercial vehicles, especially in the medium and heavy truck industry; At the same time, we aim to achieve a 50% reduction in carbon emissions by 2030 through the layout of multi fuel power platforms around traditional internal combustion engines, as well as the layout of fuel cells, pure electric powertrains, and other technologies.

In the second step, Cummins will gradually layout around numerous new energy solutions, while accelerating investment in new energy infrastructure such as renewable power grids, and promoting the maturity of low-carbon and zero carbon technologies.

The third step is to achieve the maturity and large-scale application of zero carbon technology by 2050, which can reduce an additional 1.4 billion tons of carbon emissions cumulatively, equivalent to the shutdown of all trucks on Earth for 3 years.

Wang Pan said, "Currently, Cummins has formed a carbon reduction path that combines advanced internal combustion engines and various carbon emission solutions. In terms of hydrogen fuel, it has already laid out in the upstream hydrogen production field, achieving a full industry chain layout from use to production

According to Fangde.com, Cummins PEM (Proton Exchange Membrane Electrolysis Water Technology) electrolysis water hydrogen production project has been implemented and applied in many parts of the country. The renewable power electrolysis water hydrogen production demonstration project of Sinopec Zhongyuan Oilfield, located in Puyang, Henan Province, has an annual production capacity of nearly 400 tons and is currently the largest PEM electrolysis water hydrogen production project in China.

02

Parallel multi technology routes

Focus on maximizing customer benefits

Cummins has always been committed to achieving the best TCO for its customers, and the same goes for its path towards low-carbon and zero carbon development. For this purpose, Cummins conducts an annual analysis of the customer's total cost lifecycle to determine the amount of technical resources to be invested in different stages. ”On the forum, Wang Pan emphasized so much.

Wang Pan said that taking medium and heavy-duty trucks as an example, the main cost for customers is fuel. In short, drivers choose whatever fuel is cheap. If the price difference between natural gas and diesel remains at the level of 2 yuan, the proportion of gasification in the domestic medium and heavy truck industry will rapidly increase in the near future. Natural gas is also a low-carbon fuel, which can achieve a carbon reduction rate of about 15%.

According to publicly available information, Cummins is partnering with PACCAR and multiple transportation companies such as FedEx Freight and Knight Swift in the North American market to showcase the enormous potential of 15N natural gas engines in reducing emissions during long-distance transportation. Pekka will equip its Kenworth and Peterbilt brand trucks with Cummins 15N natural gas engines. As a Cummins multi fuel engine platform product, the 15N natural gas engine can significantly reduce the carbon footprint of fleets while meeting their transportation power performance requirements.

Secondly, Wang Pan also shared some thoughts on Cummins' hydrogen fuel technology roadmap.

Hydrogen energy is equivalent to three times that of diesel. With the development of technology, hydrogen internal combustion engines have great market prospects. With the further maturity of hydrogen production and combustion technology, the power combination of hydrogen internal combustion engines and low-cost fuels will undoubtedly create greater value for customers and be more conducive to the green and high-quality development of the industry, "Wang Pan judged.

03

Exploring technological leadership

Integrated power chain layout

In 2022, Cummins announced the acquisition of Mercedes Benz. This is not only an important milestone for Cummins to move towards zero carbon solutions, but also further enriches Cummins' product portfolio of components, consolidating Cummins' future positioning as a provider of powertrain technology solutions.

Wang Pan said, "Currently, Cummins has achieved a layout of integrated power chain for the entire vehicle, mastering integrated power chain control technology including engine, gearbox, aftertreatment, and axle. Based on leading technological strength, Cummins fuel products also have strong fuel saving and emission reduction capabilities

It is reported that in terms of fuel products, Cummins achieves a 10% fuel savings in power chain technology by adopting direct transmission rear axle and ultra-low rear axle speed ratio technology; The gearbox can effectively save fuel by 10% -20% through energy recovery technology, hybrid technology, and waste energy recycling application technology; The integrated power chain control technology can save 5% fuel.

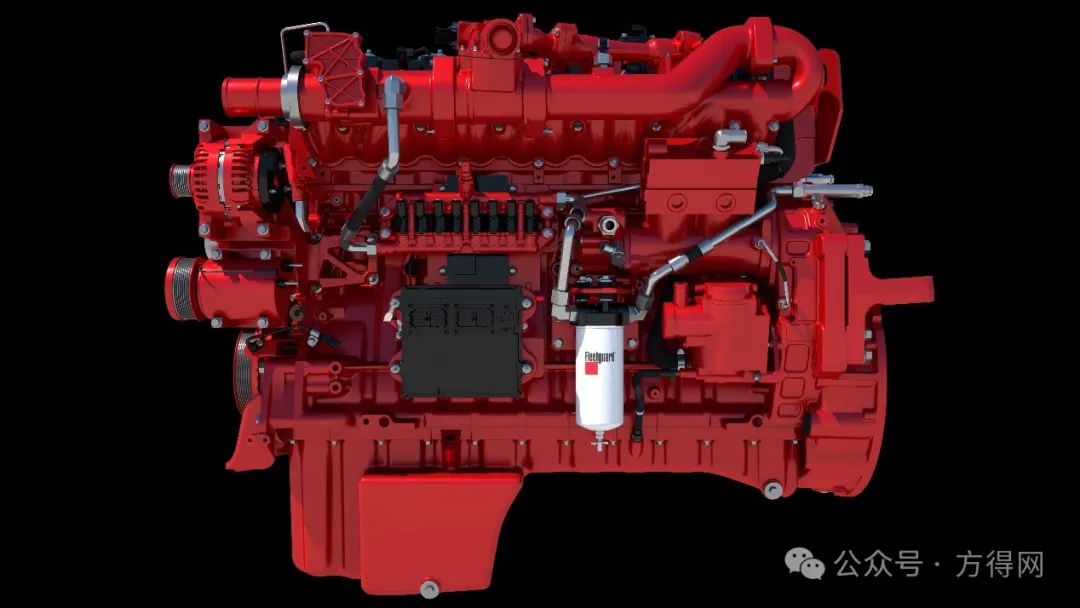

Wang Pan further stated, "In the future, Cummins will continue to explore and develop ultra high efficiency diesel engines, further improving the thermal efficiency of internal combustion engines to 55% -57%. For example, combustion efficiency can be optimized through technologies such as fuel injection, intake and exhaust efficiency can be improved through intake and exhaust, cam optimization, and friction loss can be reduced through cooling and lubrication technology. Cummins still has a 10% technical reserve in the long run to improve diesel engine fuel consumption

In terms of hydrogen internal combustion engines, it is reported that Cummins has developed two high thermal efficiency hydrogen internal combustion engines, B6.7H and 15H. This type of engine is based on Cummins' global resource collaboration and local research and development, with features such as customized design and integrated optimization; Independent research and development of core components, modular design; Simultaneously, it can achieve universal use across multiple fuel platforms, ensuring safety and reliability.

Wang Pan said frankly, "Cummins hydrogen internal combustion engine has advanced technology, excellent performance, and thermal efficiency of up to 44%. Its 15L model can achieve 410kW high power, and the maximum torque can reach 2600Nm."

In the short term, Cummins will focus on the development of natural gas and diesel engines, continuously reducing costs and increasing efficiency for customers, while empowering the industry to develop energy conservation and emission reduction. In the long run, Cummins will work together with industry partners to continuously optimize the vehicle power chain and create the lowest TCO for customers. In essence, Cummins will continue to focus on technological leadership and move forward courageously in the future. ”Wang Pan emphasized in the end.