Yuchai: Leading Guangxi's industry to strive for new quality productivity through "new" efforts

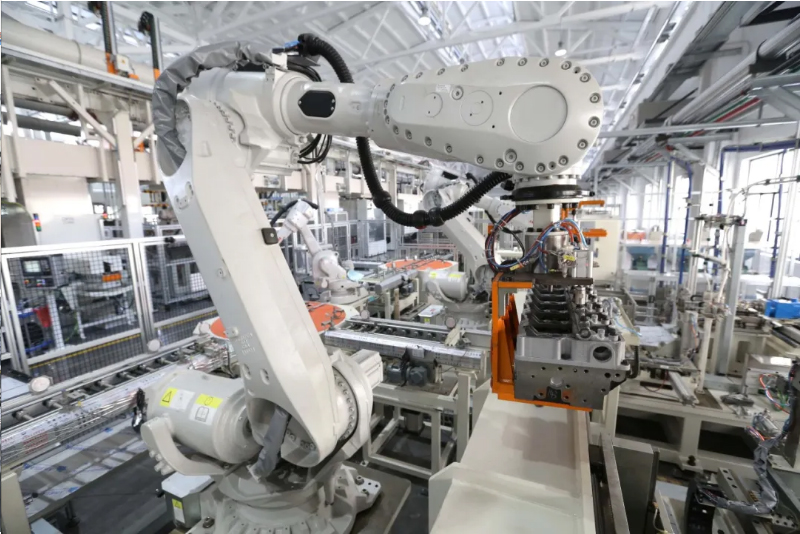

In recent years, Yuchai has invested nearly 3 billion yuan to carry out intelligent upgrading and transformation of the new generation of National VI production lines, and has built a "black light factory" that fully applies 5G technology, digital monitoring of the entire management center process, automation of the entire engine process, and unmanned production with lights that can be turned off.

According to the report, in Yuchai's quiet and temperature controlled dust-free factory, towering robotic arms and precision production lines enable automatic guided transport vehicles to flexibly shuttle and load materials. Entering Yuchai's' Black Lamp Factory 'is like entering a' future world '.

In fact, the "black light factory" is not "black" because of its high degree of automation, which can continue to operate even when the lights are turned off. The traditional processing factory workshop requires more than 100 people to operate, and now all are replaced by robots and automated machine tools, increasing efficiency by more than 90%. "Wang Yumao, Lean Improvement Director of Yuchai Machinery, told reporters that through digital and intelligent transformation, the machining accuracy of Yuchai National VI engine can reach 1 micron, which is equivalent to only 1/10 of the gap between two components, far exceeding the domestic average level and leading the industry far ahead.

Yuchai continues to accelerate digital empowerment and has created 17 autonomous region level intelligent factories and 15 digital workshops so far.

Article source: Reprinted from Yuchai Group