Industry News | Luxury car giants will never give up on internal combustion engines!

BMW's factory in Steyr, Austria is undergoing a complex transformation as it expands production of electric power systems while still maintaining its role as a global center for internal combustion engine manufacturing, "said Klaus von Moltke, Senior Vice President of Engine Production at BMW Group. He is also the Managing Director of the Steyr Engine Factory.

The internal combustion engine is our foundation. In an interview, von Moltke discussed the continued development of diesel and gasoline engines, the production acceleration of BMW's "Neue Klasse" electric vehicle architecture, and how employee cross training and digitization can help provide future security for operations.

BMW positions the Steyr factory as a dual engine factory for internal combustion engines and electric drive systems to ensure a flexible and future oriented supply model for its global vehicle lineup. Last year, Steyr had 4900 employees and achieved sales of 4.4 billion euros, ranking among the top ten industrial enterprises in Austria. It is also the core of BMW's strategy to balance traditional and future power systems.

We are very proud at the Steyr factory, "said von Moltke. The factory has been designated as the global development and production center for the upcoming 'new generation' platform in 2022.

This transformation has not been smooth sailing. In the preparatory stage, there are indeed many unstable factors, "said von Moltke.

Due to Steyr's heavy reliance on internal combustion engines, local employees have questioned its long-term feasibility.

But with the company's decision to build Steyr as the center of electric drive systems, the situation changed. Feng Maoqi said, "This measure provides a guarantee for our future after 2030

This decision depends on the combination of production and research and development capabilities of Steyr company.

The dual advantage of balancing research and development with production in one location

We have both research and production capabilities in the same location, "said von Moltke. This is undoubtedly a strategic advantage, as we can industrialize good ideas in the shortest possible time

However, BMW has not given up its internal combustion engine business. Feng Maoqi said, "Internal combustion engines are our foundation and provide financial support for future business." Last year, the factory produced about 1.2 million internal combustion engines to supply the global market.

BMW continues to invest in improving traditional engines, including compatibility with new fuels such as HVO100 for diesel, and compliance with the upcoming Euro 7 emission standards. We are continuing to advance the development of technology, "said von Moltke, pointing out that the focus of long-term planning is on the flexibility of technology.

We are open to all technologies and offer all options, without causing overcapacity, "he said. Our task is to position ourselves in a favorable position so that we can best serve the market

To support this dual track strategy, BMW is implementing flexible production methods and multi skilled employees. Our goal is to enable all employees to master all technologies, "said von Moltke. We have a highly flexible production system that can serve two fields simultaneously

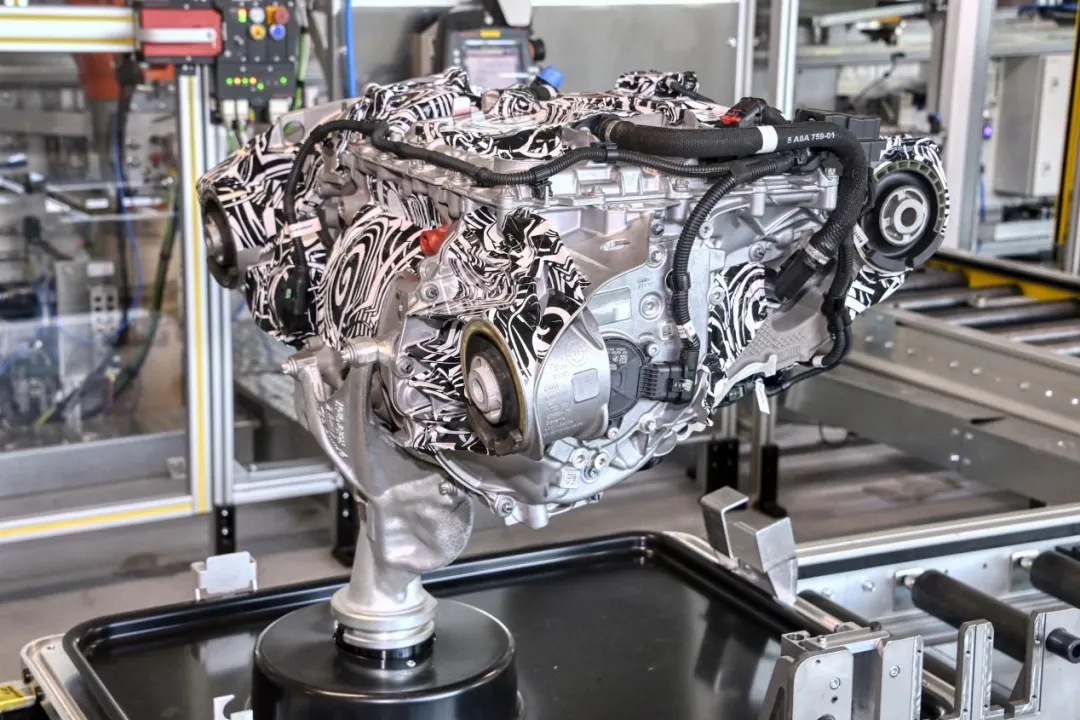

The transition to electric vehicle production has also introduced new technological components, such as inverters - efficient, high-precision components manufactured under clean room conditions.

So far, we have been purchasing these components from external sources, "said von Moltke. We believe that inverters are a key component that sets us apart from our competitors and provides enormous potential for further improving the efficiency and performance of electric drives

Energy saving and weight reduction achieved through the latest electric drive system

Von Moltke stated that the progress can already be measured by comparing BMW's current fifth generation electric vehicle drive system with the upcoming sixth generation. We have reduced energy consumption by 40% and significantly reduced vehicle weight, resulting in a 30% increase in vehicle range

However, this transformation is not yet complete, and the application of digitization in the manufacturing process plays a crucial role, especially due to the high costs in the region where Steyr is located. Therefore, digitization is an important driving factor for the sustainable development of the factory in the future, "said von Moltke.

Although some people believe that the production of electric drive systems is simpler, von Moltke said that the actual situation is much more complex. In terms of work content and depth, our production level is comparable to that of internal combustion engines, "he said, pointing out that BMW's approach covers the deep integration of stator, rotor, and transmission components.

This also provides a basis for the company's personnel allocation strategy. Our plan is to maintain the current staffing level by 2030- about 4900 employees, of which 700 are engaged in research and development work, "said von Moltke.

In terms of production capacity, BMW expects to continue producing 1.2 million internal combustion engine vehicles annually, while the production capacity of electric drive systems will be expanded to 600000 sets across two production lines. The production ratio of combustion power and electric drive will be adjusted according to market demand, "he said.

Steyr's work in the 'New Generation' project has been fully launched. Since BMW made the relevant decision in September 2022, the factory has rapidly advanced the completion of construction projects and the installation of equipment.

By last summer, we had installed the equipment and then delivered the first batch of pre production components from that location to the 'New Generation' production factory in Debrecen, Hungary. ”Feng Maoqi said.

The first 'new generation' model will be mass-produced in the autumn

The series production of the first "new generation" model iX3 will start in the autumn at BMW's new factory in Debrecen. The pre production of the second production line will also start around the same time.

Steyr will serve all global markets except for China, while BMW operates independent localized engine production in China. This is more due to market distance and necessary supplier networks, rather than tariff issues, "said von Moltke.

When asked if increasing demand would lead to global expansion of production, von Moltke stated that the company regularly evaluates all production plans. If expansion is necessary, we also have corresponding plans, "he said.

As for the deadline set by the European Union to stop selling internal combustion engine cars by 2035, von Moltke refused to comment. Our task is to consider all possible scenarios, prepare for each one, and ensure that we can complete the delivery, "he said.

Another pressing challenge is the potential raw material risk faced by electric motors. Although the newly launched SSM drive system is not related to rare earths, von Moltke acknowledges concerns about recent export licensing regulations in China.

At present, he said, "There is no risk in our production increase." He pointed out that BMW's approach is to focus on flexibility. We have made investments, production facilities are ready for mass production, and the team can ensure continuous supply, "said Feng Maoqi.

compile / Qian Yaguang

edit / Huangda Road

design / Zhao Haoran

Article source / www.autonews.com By Nathan Eddy