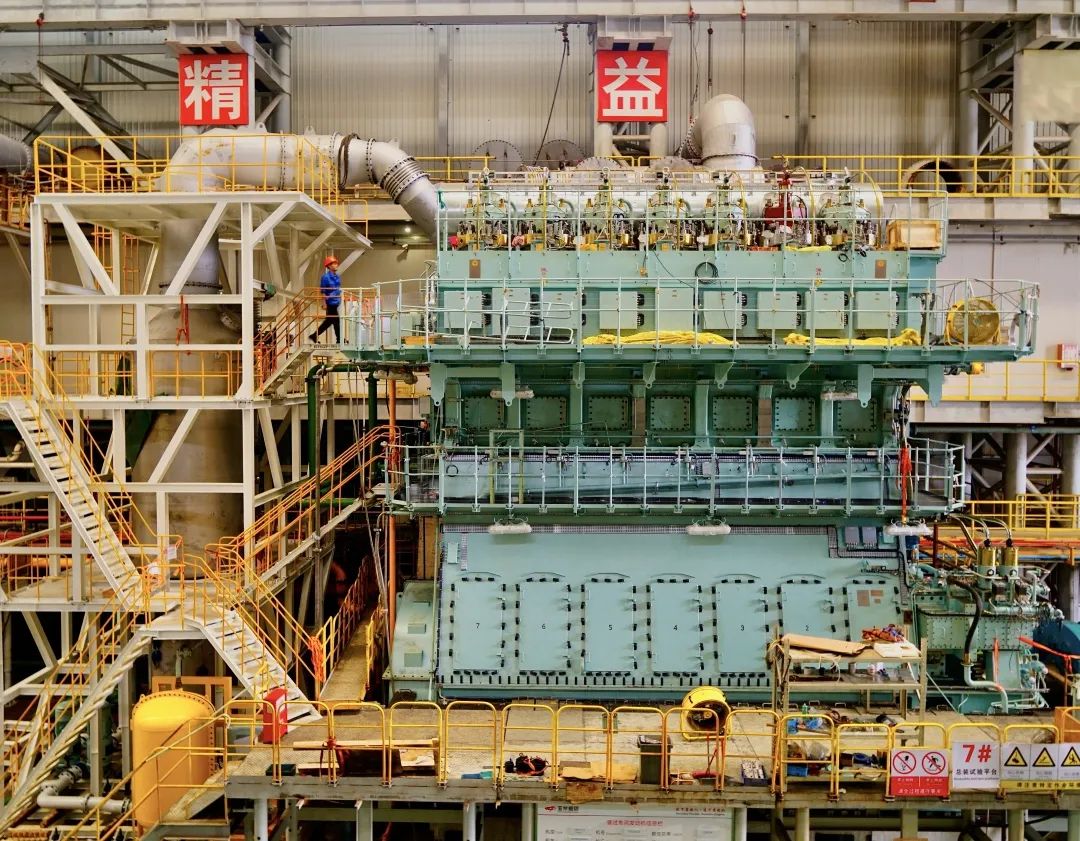

Yuchai Ship has successfully delivered the world's first 7X62DF-2.1 dual fuel engine equipped with iCER Diesel mode for inspection

Recently, Yuchai Shipbuilding successfully delivered the world's first 7X62DF-2.1 dual fuel engine equipped with iCER Diesel mode, and completed the production and delivery of a 620mm large bore low marine low-speed engine for the first time. The shipowner, shipyard, DNV, CCS, BV classification society, WinGD and other units sent representatives to the site for this inspection. With rich experience in manufacturing low-speed engines for dual fuel ships and careful preparation, Yuchai Shipyard's inspection process was very smooth and received unanimous recognition from representatives from all parties. The successful delivery of this product is not only a reflection of Yuchai Shipbuilding's ability to deliver large bore low-speed engines, but also another proof of Yuchai Shipbuilding's commitment to the most advanced dual fuel marine low-speed engine manufacturing technology, marking a new leap forward for Yuchai Shipbuilding.

The host is classified by DNV classification society, with a designed maximum output power of 22698 horsepower and equipped with the latest generation of WinGD intelligent control exhaust gas recirculation (iCER) system. Whether operating in diesel or gas mode, it can meet the requirements of the most stringent NOx emission regulations Tier III of the International Maritime Organization. The host will be installed on a 7000 car transport ship built by Wuhu Shipyard for Chery Holdings Group.

After the project order came into effect, Yuchai Shipping immediately organized a special meeting to communicate and disclose project order information, technical preparation, production layout, and other aspects. A project working group was established to develop a detailed project work plan and carry out various tasks in an orderly manner. Difficulties and deficiencies were analyzed from multiple perspectives such as "personnel, machinery, materials, methods, environment, and testing", and specific measures were communicated and formulated to effectively solve problems; For example, completing the expansion and renovation of natural gas supply to ensure that natural gas meets the needs of high-speed train testing; Complete the expansion and renovation of the sanding and painting rooms in the structural workshop to ensure the sanding and painting of structural components; Completed the design and production of over 60 new fixtures, including the iCER processing system platform, to ensure the production and manufacturing of the host; Production technology quality issues are closely coordinated by various departments to solve them in a timely and effective manner, ensuring the smooth delivery of products; Closely coordinate with the patent holder WinGD and service providers from manufacturers such as iCER, remote control, high-temperature valve, turbocharger, etc., to ensure the performance debugging of the host under various working conditions. We have completed the high-quality delivery of the world's first 7X62DF-2.1 dual fuel main engine equipped with iCER Diesel mode.

The successful delivery of this inspection is another manifestation of Yuchai Ship's reliable manufacturing technology and high standard quality requirements for dual fuel marine low-speed engines. Yuchai Ship has always adhered to the core cultural concept of "being a reliable person and building a reliable machine" and the mission of "creating value for customers with power", and will continue to provide green and reliable products for global ships.

Article source: Reprinted from Yuchai Ship Power