- Release time;2023-09-25 00:55:59

Changchai Co., Ltd

Booth Number: 6C15

Company Profile

Changchai Co., Ltd. is a national industrial enterprise with a history of over 100 years. It is one of the earliest professional manufacturers of internal combustion engines in China and the first listed company in the national agricultural machinery industry and Changzhou City. It has an annual production capacity of 800000 diesel engines, over 50000 tons of castings, and 200000 gasoline engines. Changchai has produced over 30 million diesel engines to date and has exported them to 78 countries and regions. Changchai mainly produces small and medium-sized diesel engines with a power range of 1.62-117.6 kilowatts, with more than 1000 varieties. The products are widely used in pickup trucks, light trucks, low-speed cargo vehicles, tractors, harvesters, gardening machinery, plant protection machinery, high-speed rice transplanters, generator sets, engineering machinery, cold chain and ships, and other fields. It is an enterprise in the national small diesel industry with a full range of product varieties, wide power coverage, excellent product quality, high popularity, and independent intellectual property rights for its leading products.

Partial product display

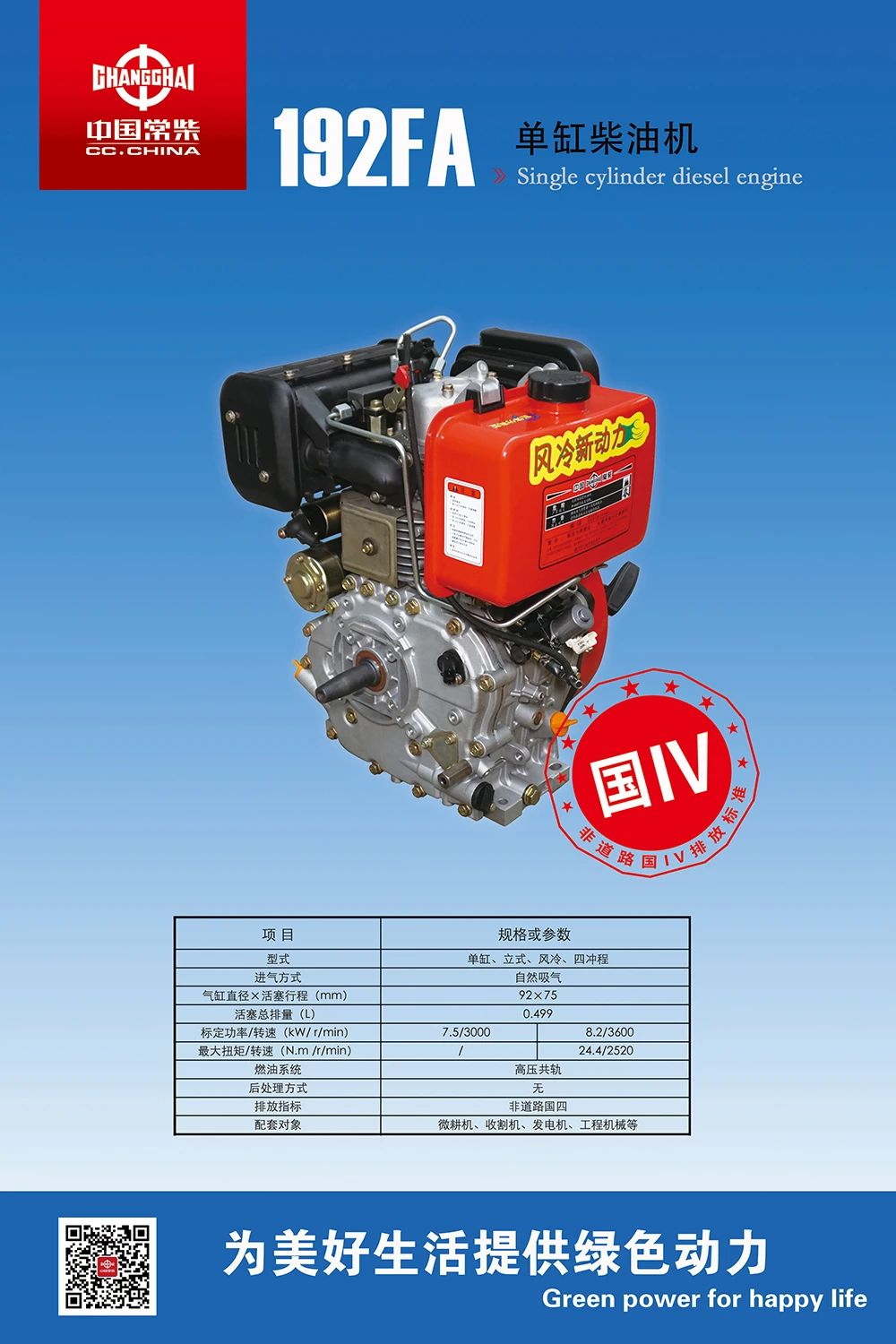

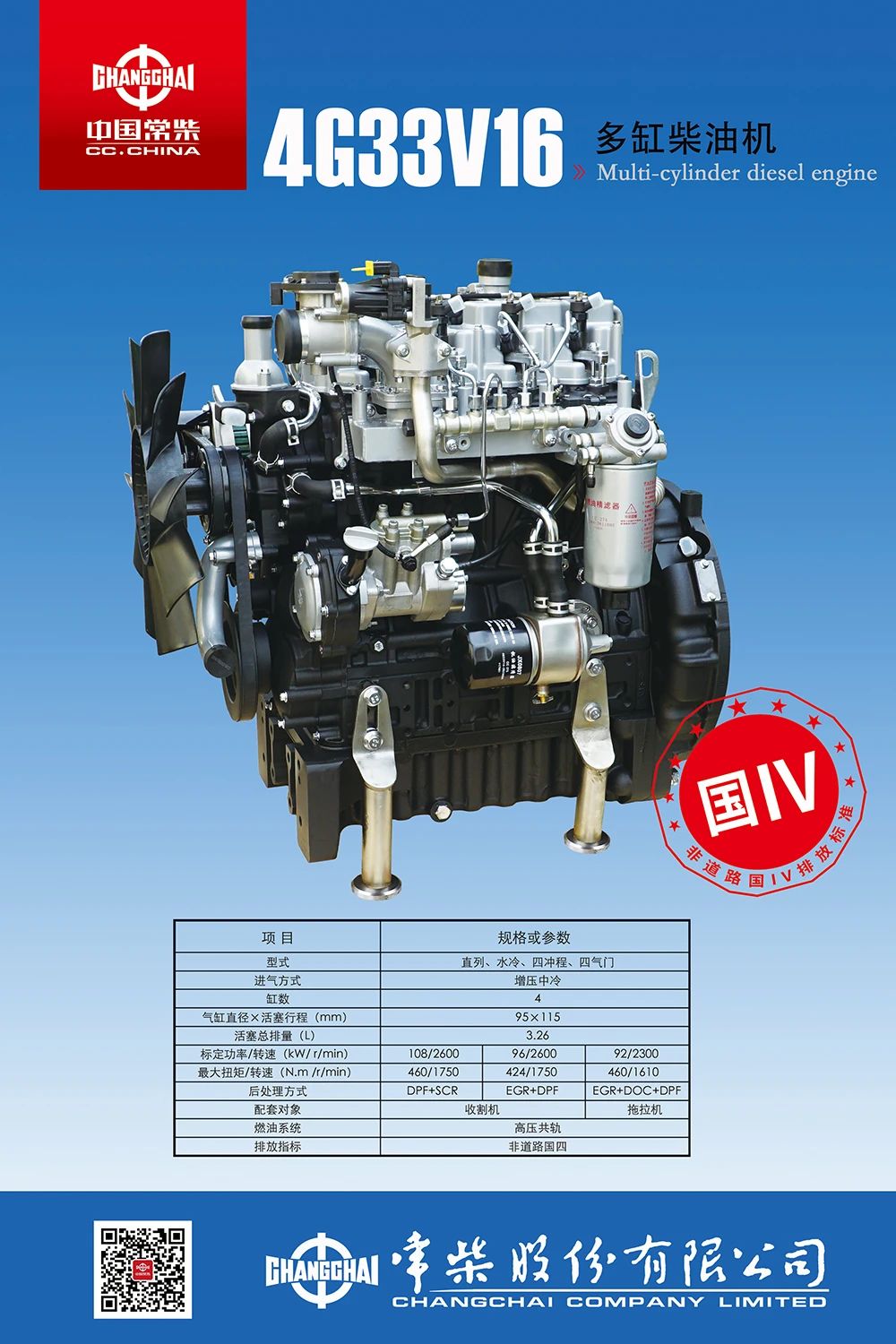

| 01 192FA |

1. Adopting a high-pressure common rail fuel system to meet non road National IV emission regulations, significantly improving fuel economy;

2. Re optimize the design of key components to enhance the reliability of diesel engines;

3. Precise control of pre injection and main injection significantly reduces engine vibration and noise;

4. The output characteristics of the engine can be precisely controlled to ensure better performance of various engines.

|

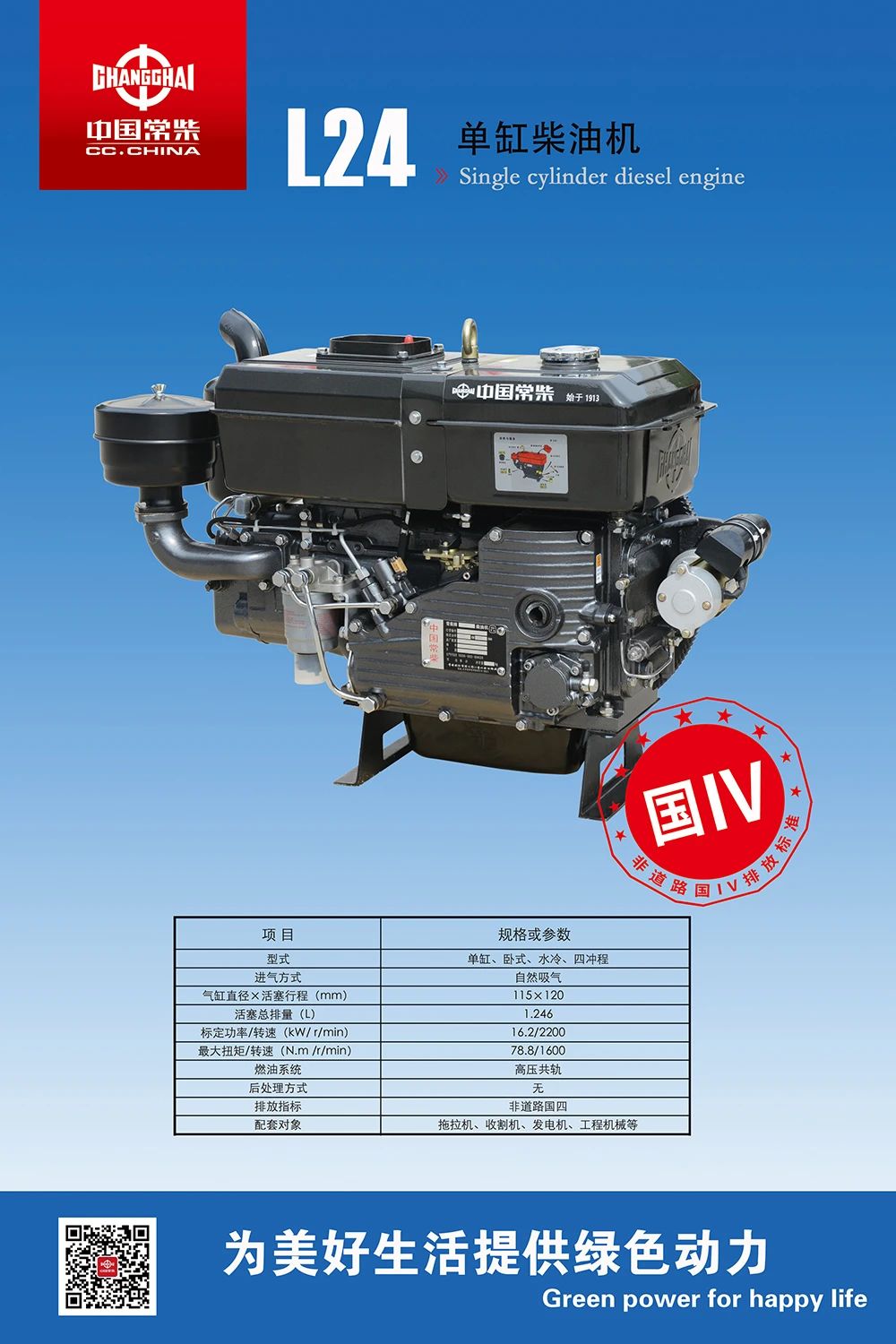

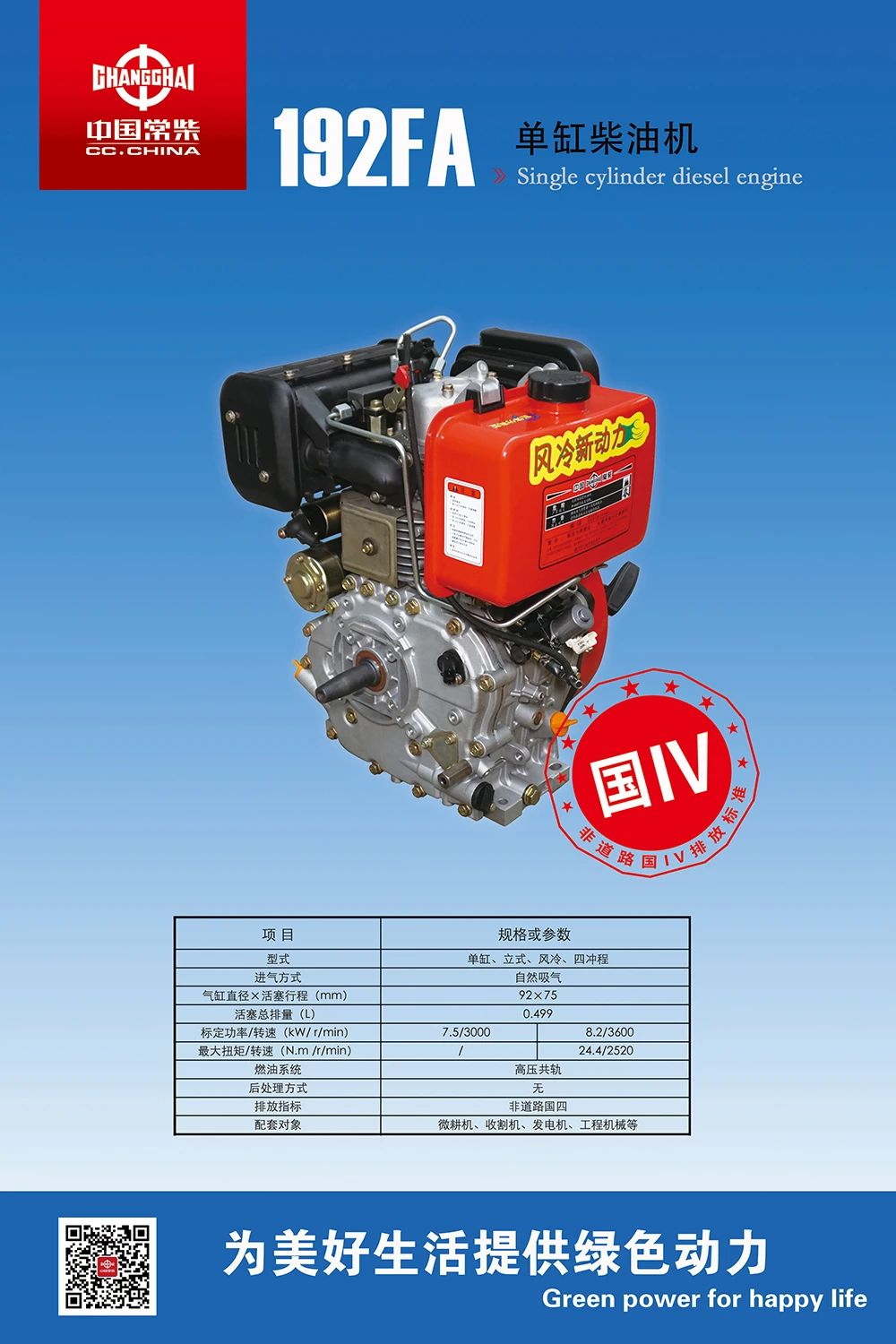

| 02 L24 |

1. High pressure fuel injection system: The fuel pressure building process and injection process are separated, and the injection is controlled by the ECU to open and terminate the injector solenoid valve, maintaining stable high-pressure fuel injection and accurately controlling the injection timing and quantity. Effectively improve the performance of diesel engines, reduce emissions, and meet the non road National IV emission standards;

2. Low noise and idle speed: Adopting a common rail system to achieve multiple quantitative injections, effectively reducing combustion noise and achieving low idle speed;

3. Good cold start performance: high injection pressure, improved oil and gas mixing quality, effectively reducing cold start time and starting smoke;

4. High reliability: Adopting a dual oil lubrication system, optimizing the structural strength of components, and improving reliability;

5. Good interchangeability: The installation dimensions and external dimensions are the same as the original ZS and L. Easy for users to upgrade and replace.

|

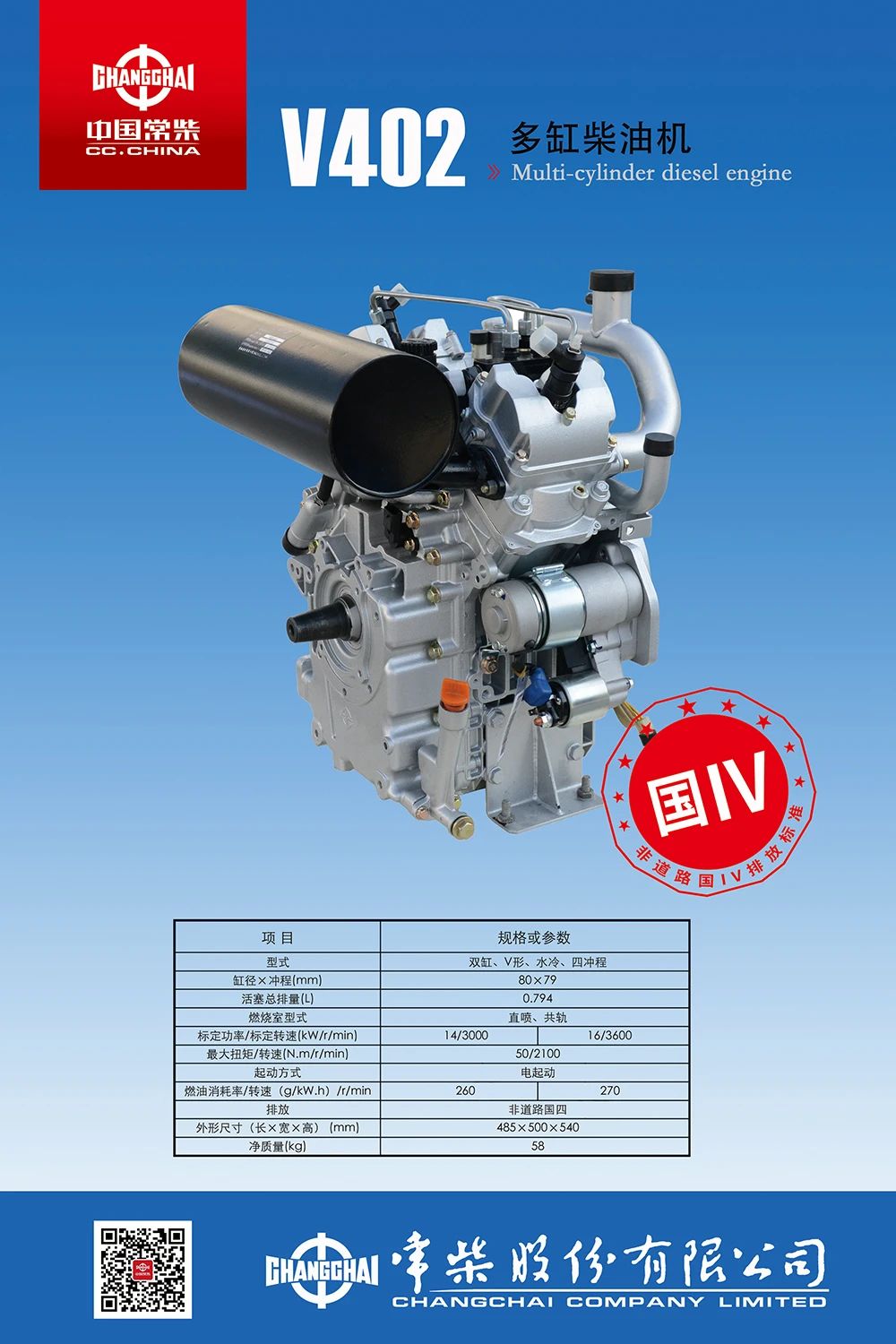

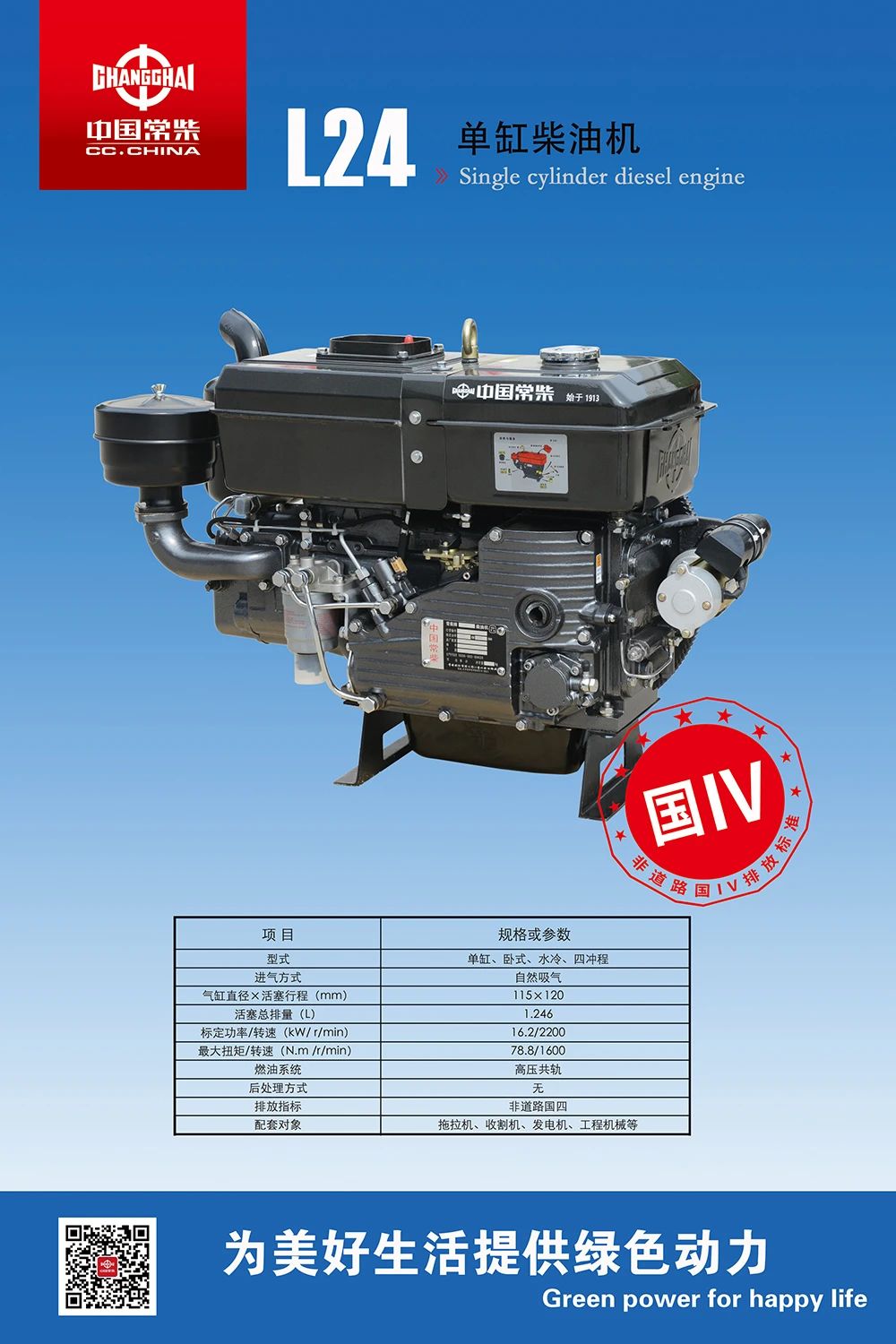

| 03 V402 |

1. Good economy, using high-pressure common rail injection system;

2. Low noise, using multiple injection technology, low combustion noise;

3. Good emission performance, meeting the National IV emission standards;

4. Compact structure and good reliability;

5. Lightweight design, with a total weight of 58kg;

6. With independent intellectual property rights and 6 national patents.

|

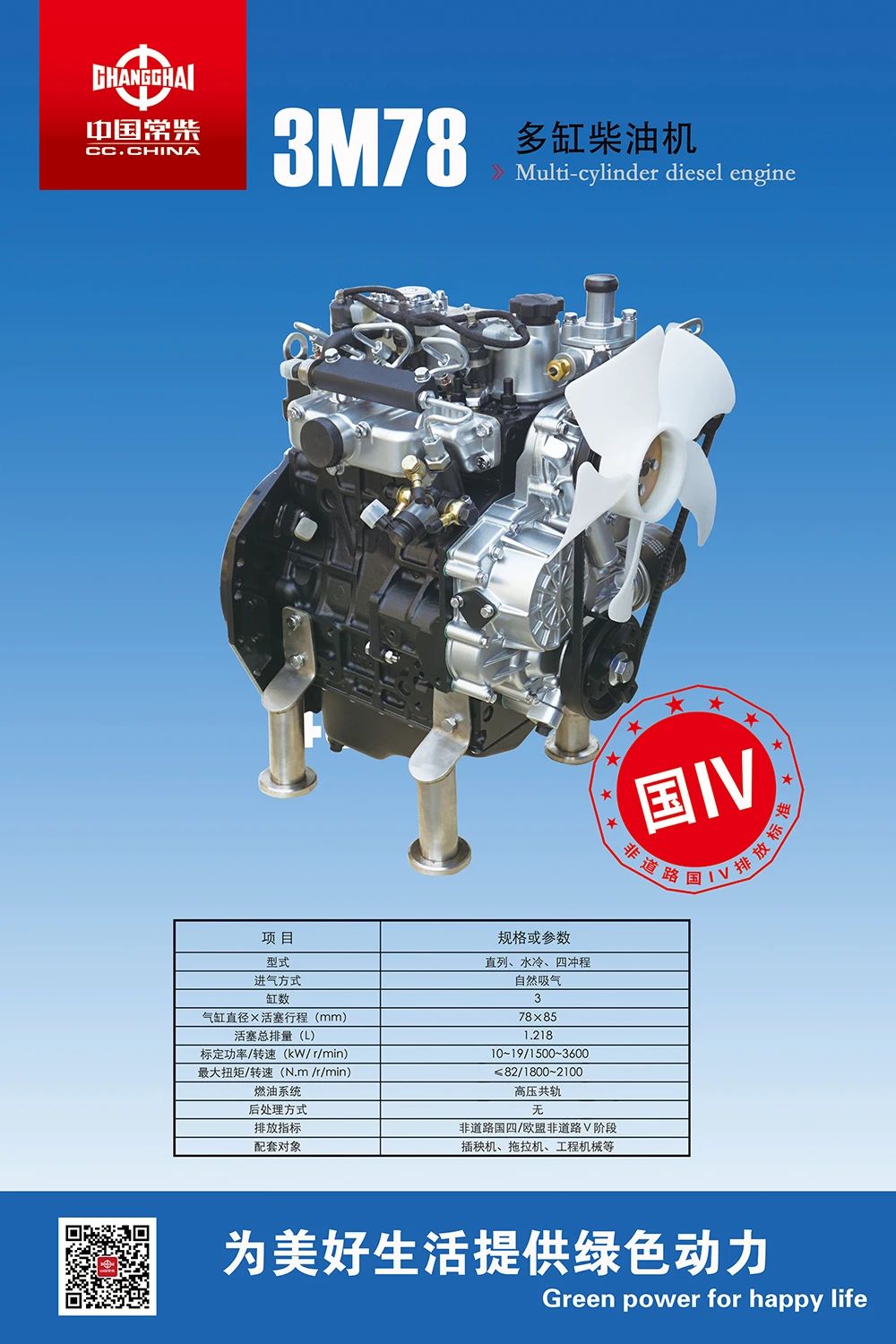

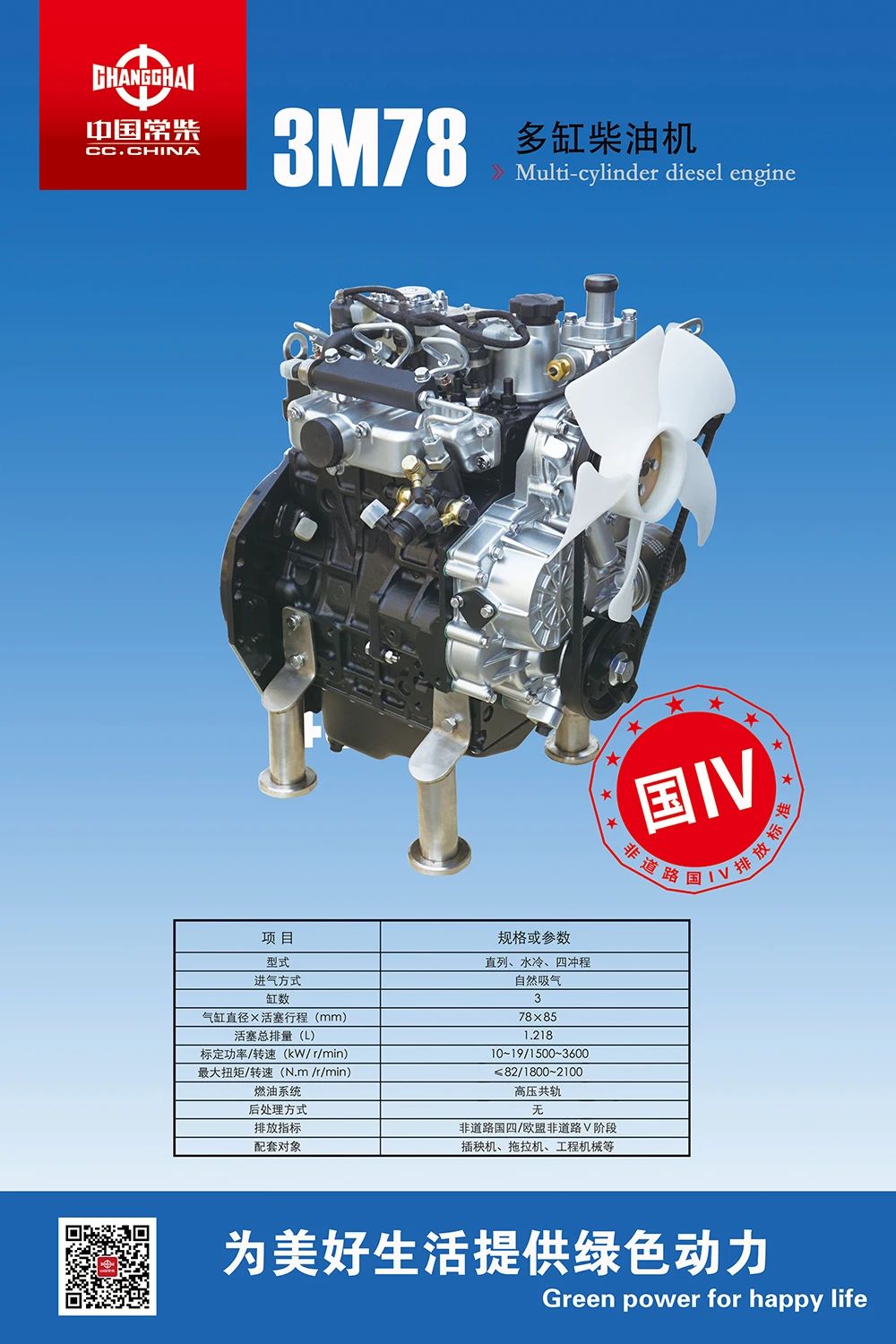

| 04 3M78 |

1. Lightweight appearance: Miniature, lightweight, and integrated design, efficient and material saving;

2. Compact and advanced structure: tunnel type body with good overall stiffness and strength; Split type fuel injection pump, compact design; Multiple power output ports, capable of front-end output, meeting different matching requirements;

3. Excellent performance: adopting high-pressure common rail technology, low fuel consumption, good transient response, strong loading capacity, high torque reserve rate, low noise and vibration;

4. Emission standards: low emissions, meeting the requirements of non road national emission standards;

5. Wide supporting range and strong applicability: Diesel engine series development, short stroke, strong engine applicability, meeting the needs of various small machinery such as rice transplanters, crop protection machines, tractors, and units.

|

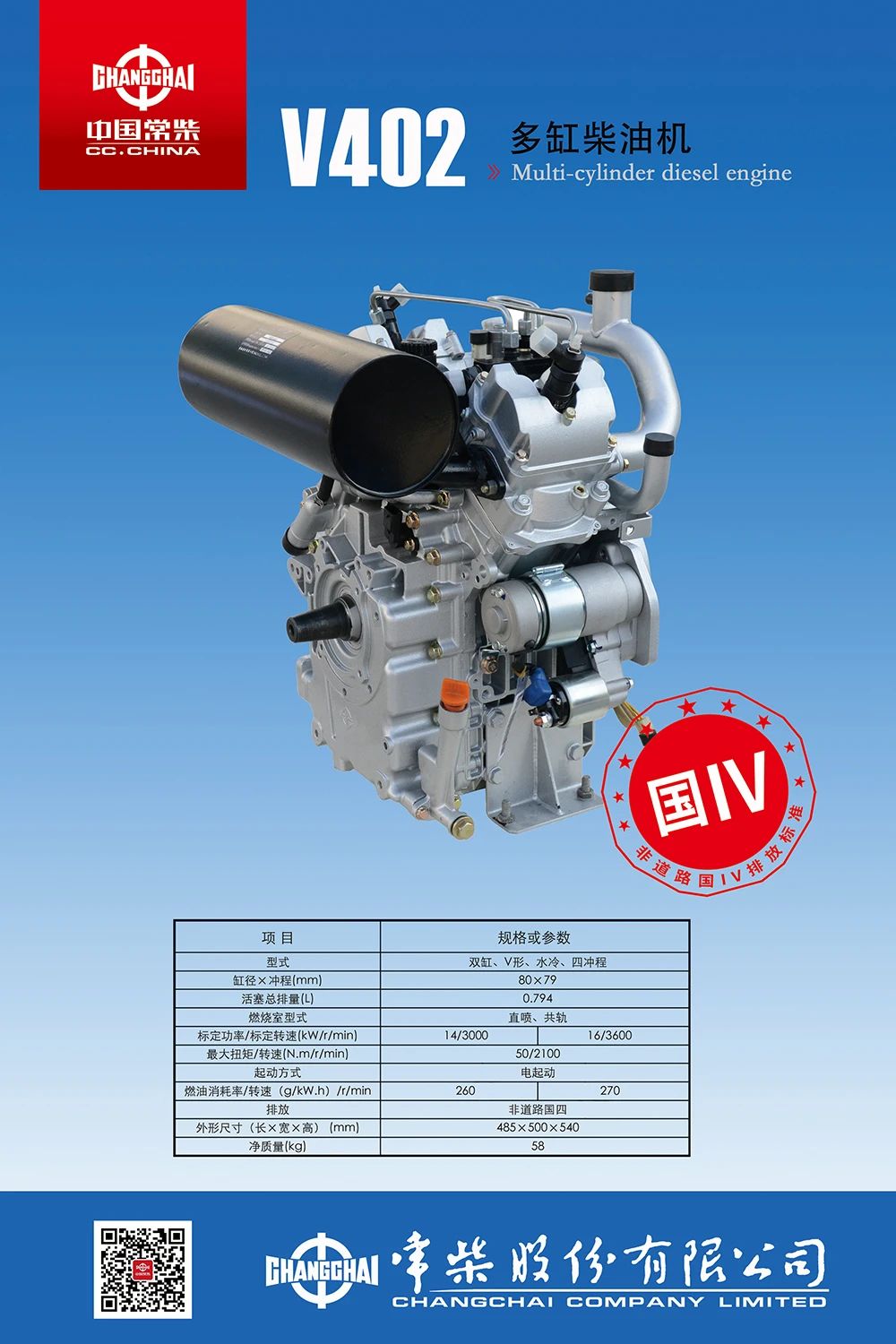

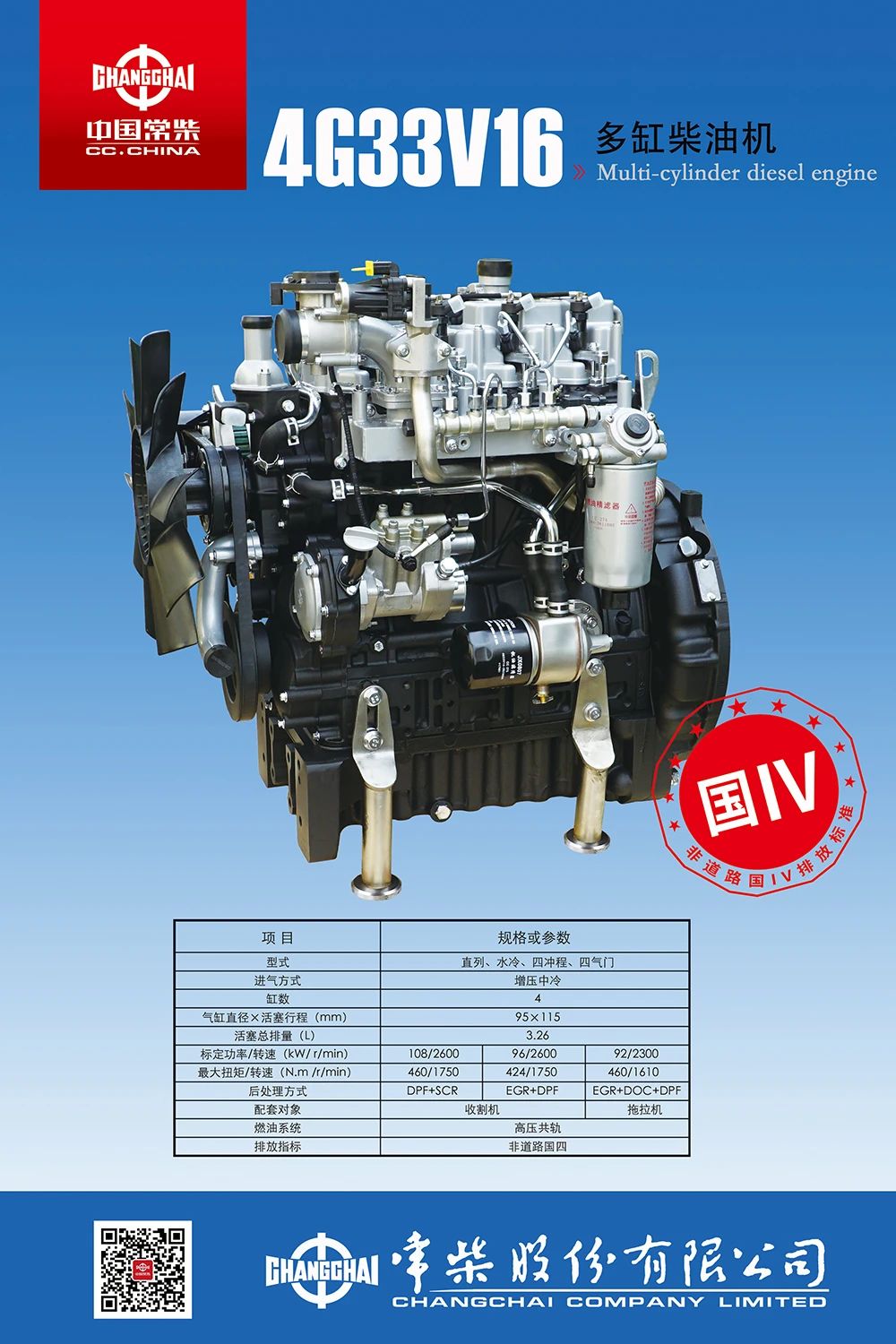

| 05 4G33V16 |

1. Adopting advanced technology and design methods for automotive engines, we have devoted ourselves to creating the first generation of long-range non road specific engines;

2. Adopting a four valve cylinder head structure to further improve the power output of the diesel engine, making the power range of the company's 95 cylinder series diesel engines more complete and meeting the needs of different users;

3. It has the characteristics of large torque reserve, good fuel economy, low noise, and low vibration;

4. In response to the requirements of reliability, torque reserve, and emission regulations for non road diesel engines, the engine body adopts an integral main bearing cover structure, equipped with inserts, internal cooling oil passage cooling pistons, deep groove rolling crankshafts, expansion connecting rods, etc., to comprehensively improve reliability;

5. Adopting the high-pressure common rail fuel system specially developed by Junfeng Electric Control Technology Co., Ltd. for non road diesel engines;

6. According to the different supporting objects and supporting power, choose different post-treatment technology routes to meet the non road national emission regulations. Adopt DPF+SCR and EGR+DOC+DPF post-treatment technologies to meet the non road national emission regulations for emissions;

7. Suitable for supporting fields such as fully fed harvesters, corn harvesters, tractors, and construction machinery.

|