- Release time;2023-09-25 02:43:33

Hunan Jiangbin Machinery (Group) Co., Ltd

Booth Number: 6C26

Company Profile

Hunan Jiangbin Machinery (Group) Co., Ltd. was founded in 1970 and is a key force in the modernization of China's national defense construction.

The company has a nationally recognized enterprise technology center and is an innovation and development base for industry university research cooperation in Xiangtan City. It continues to deepen its technological research and cooperation with research institutes, continuously improve its capabilities in technological innovation and systematic piston research and development, design, manufacturing, verification, and service. It has formed five major product system platforms, including high-performance aluminum based alloy structures, heat-resistant steel all steel structures, aluminum steel composite structures, aluminum steel hinged structures, and composite carbon fiber structures; The products involve diesel engines, gas engines, gasoline engines, and engineering engines, fully meeting the mandatory environmental regulations such as China VI and T4, and basically forming a systematic piston research and development, design, manufacturing, verification, and service system. We provide internal combustion engine pistons for more than 20 well-known domestic and foreign internal combustion engine enterprises, including automobiles, ships, aviation, engineering machinery, generator sets, high-end agricultural equipment, etc.

The company's independently developed aluminum piston reliability growth technologies, such as RGT, GR, PHC, BRC, BRC+, DSK, and thin-walled temperature controlled lightweight all steel piston technology, have been widely used in national VI products and have received unanimous recognition and praise, with broad prospects for industrialization.

The company has successively passed ISO9001:2015, GJB9001C-2017, IATF16949:2016 quality management system certification, China Classification Society factory accreditation, CNAS, DLLAC laboratory accreditation, ISO14001, ISO45001 environmental and occupational health and safety system certification, and is one of the domestic enterprises in the same industry that has also passed the military civilian commercial three standard integrated system certification; It is an executive director unit of the China Internal Combustion Engine Industry Association, a vice chairman unit of the Piston Motion Components Branch, and an executive director unit of the Hunan Automobile Industry Association.

Partial product display

| 01 High nickel cast iron ring piston |

High nickel cast iron ring piston is a conventional technology for diesel engine aluminum alloy pistons, which embeds wear-resistant high nickel cast iron rings into the first ring groove of the aluminum alloy piston to improve the wear resistance and heat load resistance of the ring groove, thereby enabling the first ring groove to withstand higher pressure and heat load.

|

| 02 Internal cooling oil passage piston |

By cooling through the oil passage, the temperature of the piston, especially the piston head and the first ring groove, is reduced to minimize engine emissions and pollution. Compared with the use of jet splash cooling, the internal cooling oil passage piston can withstand higher combustion pressure and power consumption, which is currently a conventional technology for aluminum alloy pistons in diesel engines.

|

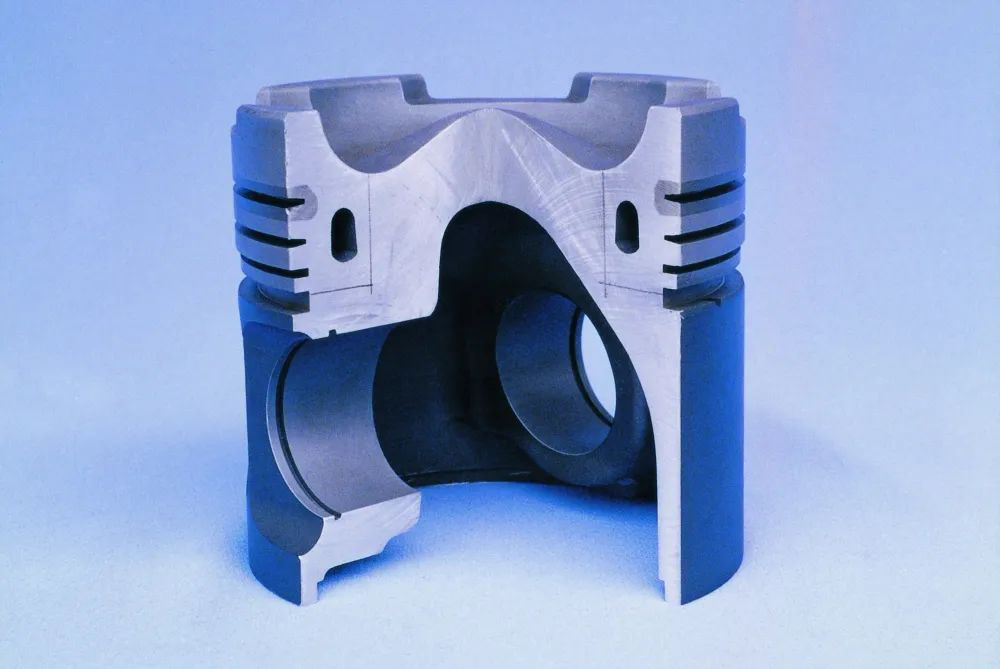

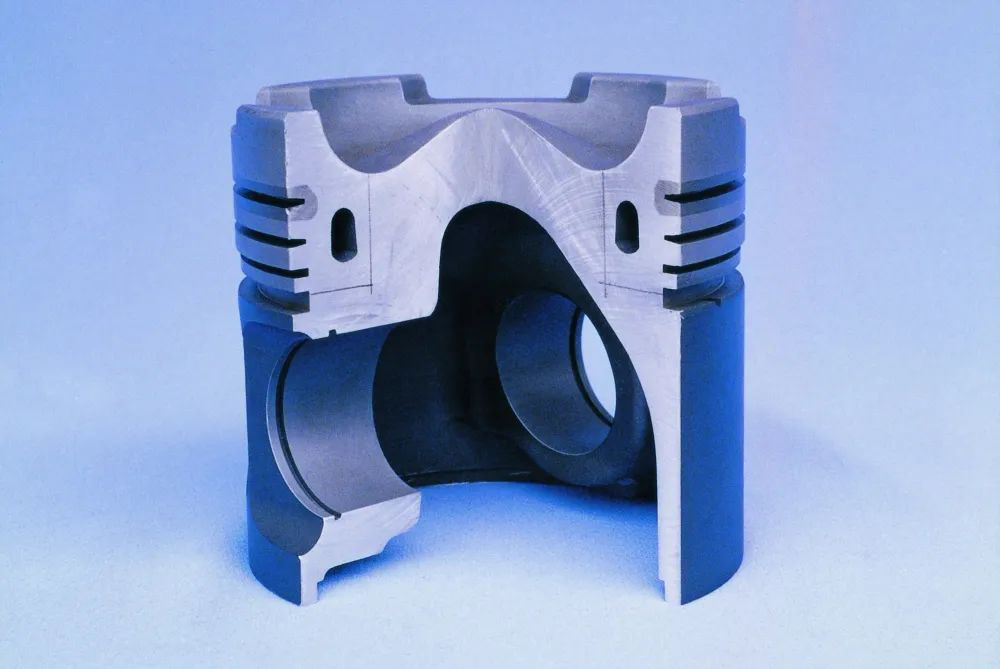

| 03 Bolt connected combined piston |

The combination piston with steel top aluminum skirt bolt connection structure has a larger cooling oil passage and a high-temperature resistant piston head, which can withstand higher combustion pressure and high temperature than aluminum alloy pistons. Its weight is reduced by about 28% compared to pure cast iron pistons, reducing inertia force while improving the piston's load resistance.

|

| 04 Electron beam welded piston |

The electron beam welded piston adopts a combined structure of cast aluminum alloy head and forged aluminum alloy skirt, which enables the aluminum alloy piston to have better skirt fatigue resistance without increasing weight.

|

| 05 Swing type piston |

The combined piston with a steel top aluminum skirt articulated structure has a larger cooling oil passage and a high-temperature resistant piston head, which can block the direct transmission of gas explosion pressure through the steel top to the piston pin and connecting rod. The steel piston top can withstand higher combustion pressure, and the thin-walled aluminum skirt can compensate for uneven thermal deformation. The clearance between the skirt and the cylinder sleeve is small, which is more conducive to skirt guidance.

|

| 06 Optimized Face Window Structure Piston |

Optimize the surface window of the non structural outer seat area of the piston, remove excess materials, and reduce weight and noise while ensuring structural strength.

|

| 07 Throat Local Remelting Piston |

By using high-energy beam to remelt and recrystallize the throat of the piston combustion chamber, a dense and uniform metallographic structure is formed, which has the effect of slag removal, shrinkage reduction, and microcrack removal, improving fatigue performance and increasing the fatigue life of the piston combustion chamber by 4-8 times.

|

| 08 Irregular oil passage piston |

Compared with the conventional elliptical regular oil passage, the piston with irregular internal cooling oil passage can improve the cooling effect due to the slightly longer residence time and more intense movement of the cooling oil in the oil passage. The top surface temperature of the piston can be reduced by 4-8 ℃, which is meaningful for improving the power of high-speed and high-power engines.

|

| 09 with copper sleeve piston |

As the main force bearing part of the piston, implanting a copper sleeve inside the piston pin hole can effectively reduce the stress on the piston pin seat, improve the structural strength of the piston, so that the piston can withstand higher mechanical loads and more severe friction and wear conditions, reduce piston pin lock failure, and improve the wear resistance and fatigue life of the piston pin hole.

|

| 10 all steel pistons |

All steel pistons greatly improve the product's resistance to high temperature and high pressure, enabling it to meet higher alternating loads and achieve higher combustibility. Its piston has high strength and compact structure, which can achieve a smaller piston compression ratio. The piston material has a low coefficient of thermal expansion and good volume stability, which can achieve lower cylinder clearance, reduce engine noise, and meet the requirements of higher efficiency and lower emissions of engines. It is currently one of the main technical solutions for pistons in China VI engines.

|

| 11 . Aircraft engine piston |

Aircraft engine pistons are mainly made of fully forged aluminum alloy pistons, which have the characteristics of high fatigue strength, light weight, and good reliability.

|

| 12 Marine Engine Pistons |

Marine engine pistons with a cylinder diameter greater than 150mm are currently mainly composed of cast aluminum alloy pistons and steel top aluminum skirt bolt connection structures. The rough forming technology is difficult, the manufacturing cycle is long, and the cost is high. They are mainly used in marine generator sets, main/auxiliary drives of ships, and some engineering vehicles and rail vehicles.

|