- Release time;2023-09-27 01:28:07

Wuxi Henghe Environmental Protection Technology Co., Ltd

Booth Number: 6E13

Company Profile

Wuxi Henghe Environmental Protection Technology Co., Ltd. was established in 2015 and is a high-tech and environmentally friendly enterprise specializing in the research and development, manufacturing, and sales of engine exhaust aftertreatment systems. Leading the way in building the core industry chain of engine exhaust aftertreatment systems. The company is headquartered in Wuxi, Jiangsu Province, and has large-scale production factories in Wuxi and Kunming.

The company's post-processing system products are widely used in the fields of automotive machinery, non road machinery, ships, etc. The main application customers include Beiqi Foton, Jianghuai Automobile, Dongfeng Motor, Changan Automobile, China National Heavy Duty Truck Group, SAIC Maxus, Jiangling Motors, China Shipbuilding Power, etc.

The company is a national level "specialized, refined, innovative" small giant enterprise, high-tech enterprise, Jiangsu Province Enterprise Technology Center, and Engineering Technology Center.

Partial product display

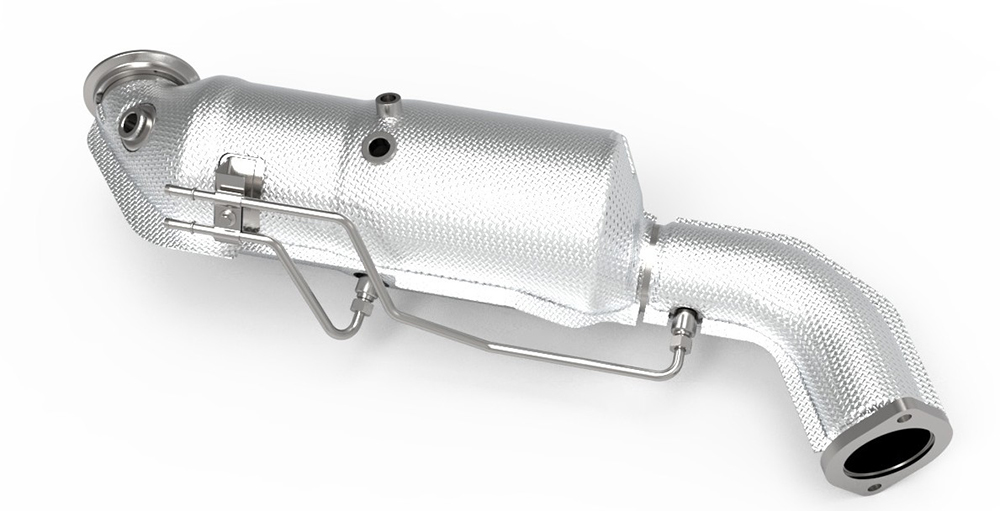

| 01 Henghe gasoline engine after treatment catalytic converter assembly |

The Henghe gasoline engine post-processing packaging production line adopts robots and automated transfer mechanisms to achieve automatic loading and unloading of carriers, liners, and cylinders, forming a fully automatic control and circulation GBD control packaging system. This system adopts soft filling packaging technology to achieve processes such as carrier diameter measurement, pad weighing, automatic wrapping, packaging, GBD shrinking, GBD verification, GBD engraving, and QR code verification. By using visual and laser sensors, in conjunction with NG (problematic materials) to select the belt body, the flow of faulty parts can be avoided. At the same time, the tail line is equipped with a scanning and recording system to achieve product quality traceability. The production line can achieve simultaneous processing of two types of diameter products, and the output of a single line shift can reach 960 pieces.

|

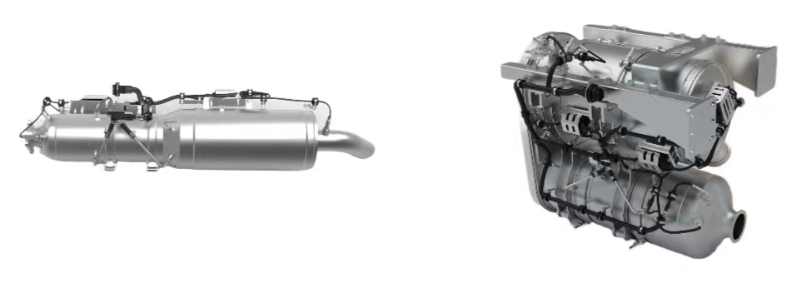

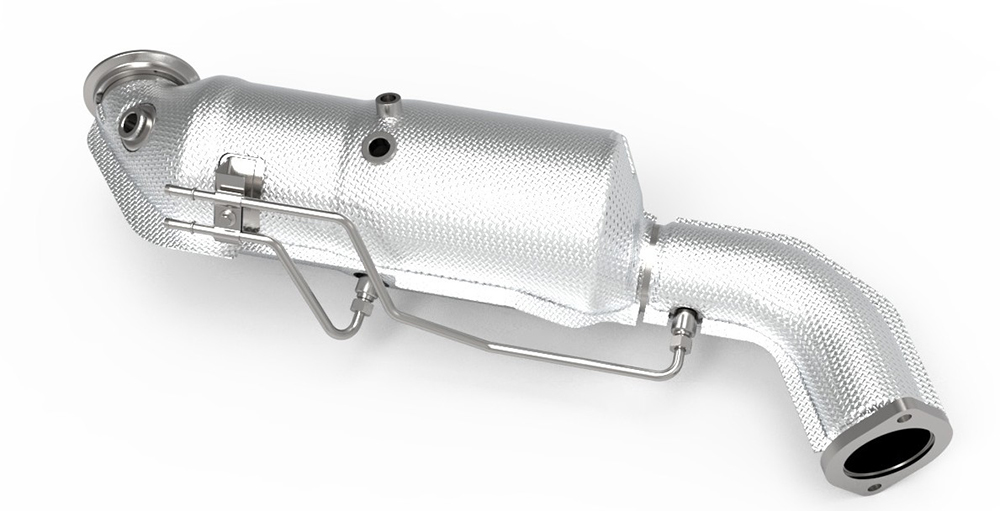

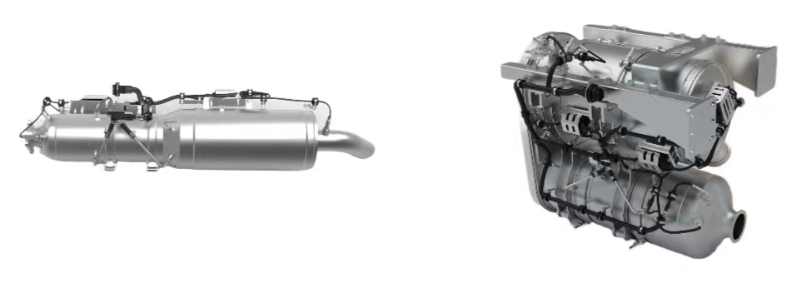

| 02 Henghe Diesel Engine Aftertreatment Catalyst Assembly |

The National VI diesel post-treatment packaging line adopts the world's mainstream packaging technology, combined with its own product characteristics, and has invested in and configured domestically leading automation equipment. The production line adopts GBD technology to achieve automation of processes such as carrier liner feeding, diameter detection, mechanical arm handling, liner density weighing, and GBD diameter reduction. Henghe has built two National VI GBD diesel production lines and plans to invest in another one by the end of 2023, which will have the capacity to produce 800000 sets of catalytic mufflers annually.

|

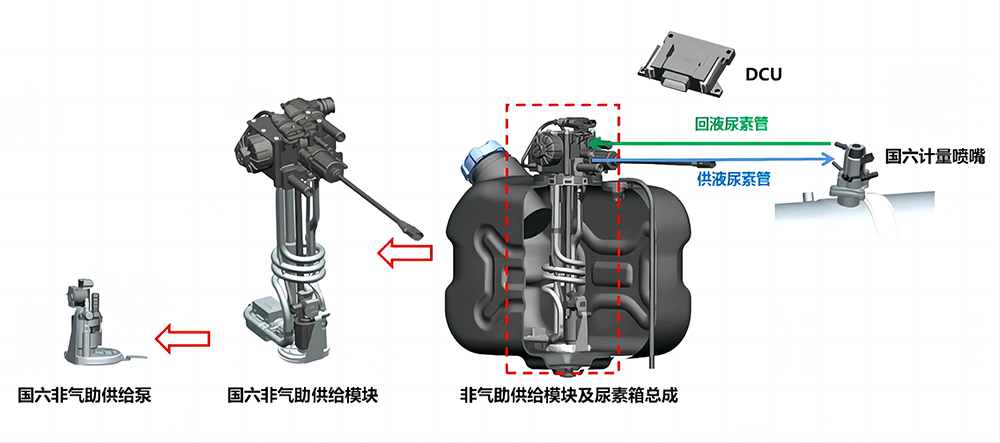

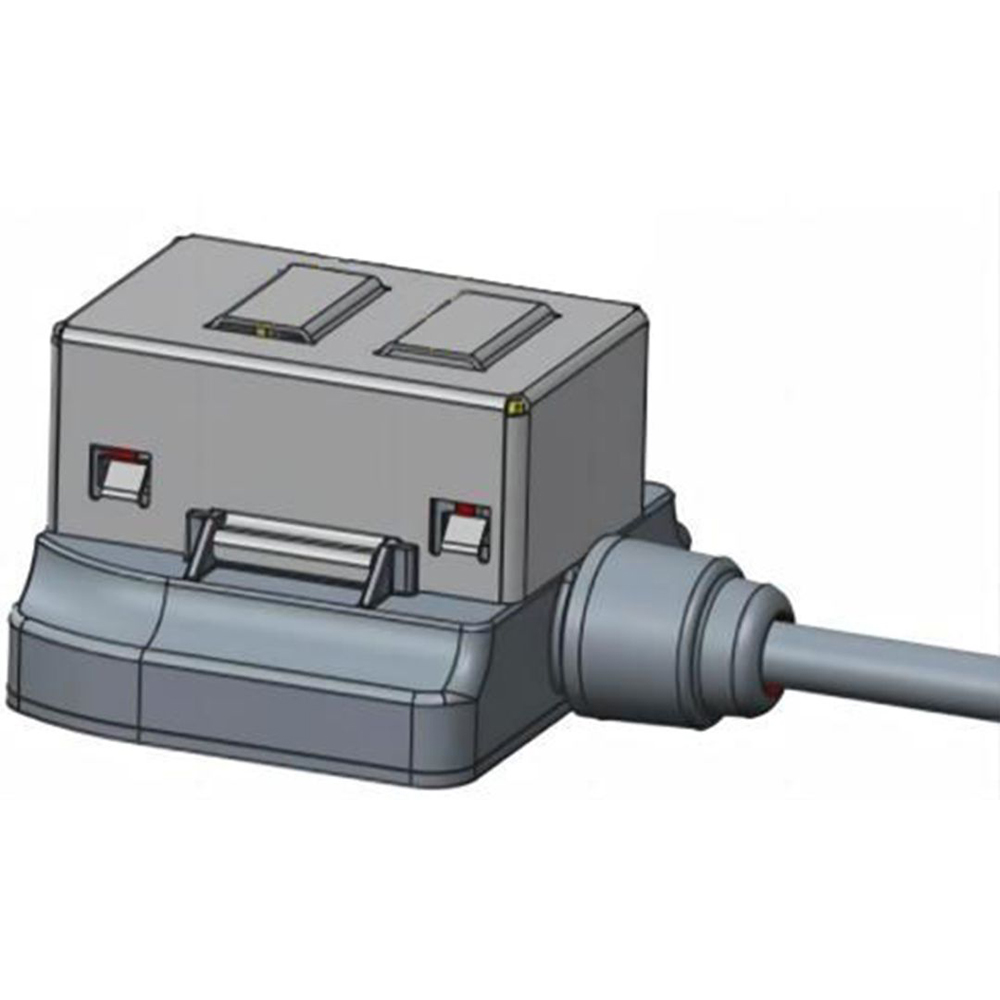

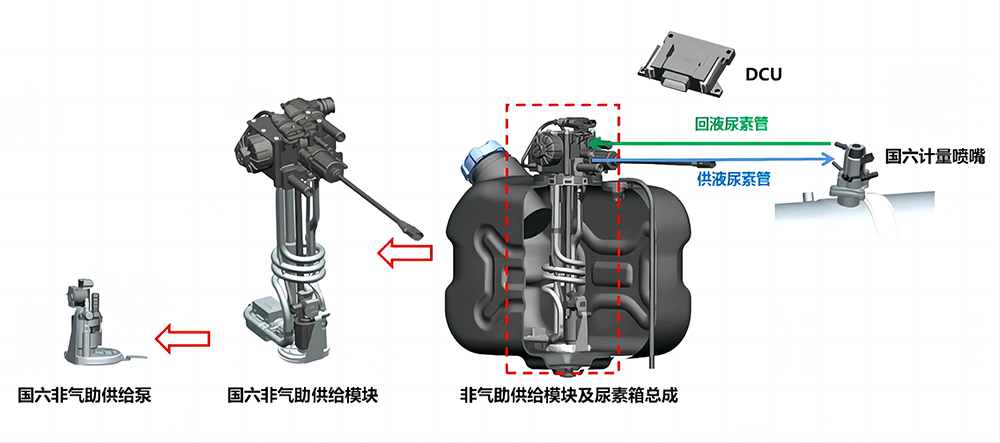

| 03 Henghe urea injection system |

Containing urea supply module, urea tank, DCU controller and nozzle. The original sleeve type liquid metering unit was the first to realize the urea metering pump embedded in the urea tank in the SCR system of heavy-duty vehicles, greatly simplifying the urea pipeline and thawing system, breaking the monopoly of foreign enterprises in the urea solution metering and injection technology route in the engine aftertreatment industry.

|

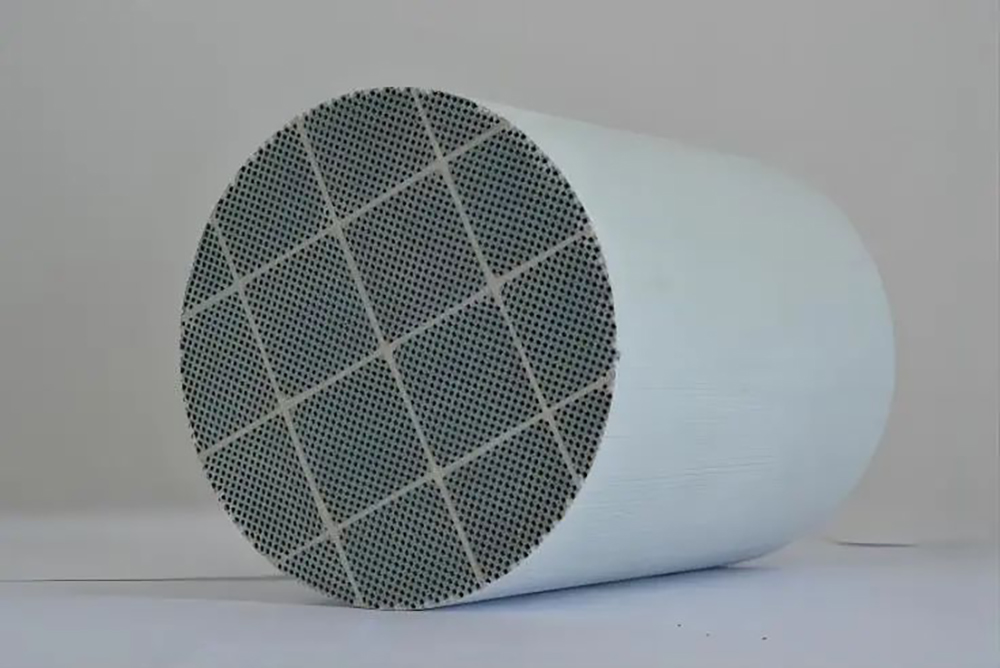

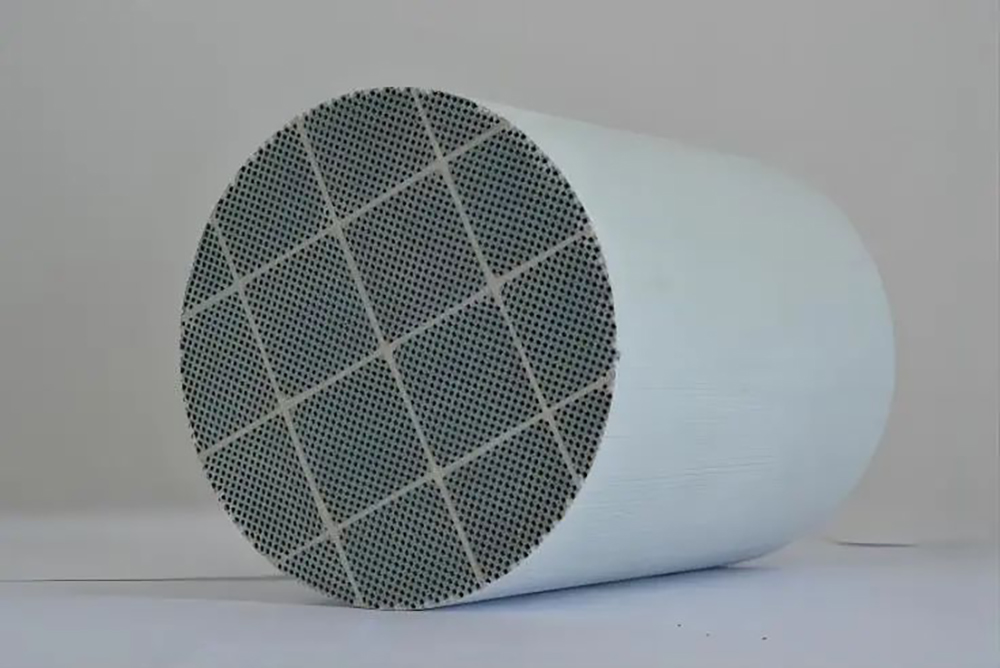

| 05 Carrier |

Contains SiC carrier and high-end cordierite carrier. Silicon carbide DPF carrier: Its performance parameters are comparable to Japan's NGK, leading domestic manufacturers in the same industry. It covers medium and light-duty National VI commercial vehicles and non road vehicles, and has been applied in more than 30000 National VI and non road T4 vehicles. It has also participated in post treatment and modification projects for commercial vehicles in Shanghai and Henan, and is exported to Germany, the Middle East and other places.

High end cordierite carrier: Currently, various sizes of carriers with 600/3 specifications have been developed and widely used in China VI light-duty commercial vehicles, with sales exceeding 100000 pieces. The high-end carrier with 750/2 specification for passenger cars is currently in the trial stage and is expected to be stably launched on the market in early 2024.

|

| 06 Lean Burn Gasoline Engine Aftertreatment Assembly (New Product) |

We plan to adopt the ultra lean combustion technology route. The development goal of the first stage post-processing system is to obtain corresponding post-processing components (SCR, urea injection system) for different post-processing technology routes, and to conduct relevant post-processing tests on the engine bench. Test the effectiveness of different post-treatment components in the lean burn post-treatment process of gasoline engines. Comprehensively evaluate the effectiveness, reliability, and adaptability of various technical routes. Develop corresponding post-processing systems to meet the 6b (RDE) emission requirements for various indicators of engine exhaust emissions.

|