- Release time;2023-10-18 22:08:46

Anhui Hengli Additive Manufacturing Technology Co., Ltd

Booth Number: 6E26

Company Profile

Anhui Hengli Additive Manufacturing Technology Co., Ltd. is a new technology company mainly engaged in independent research and development, production, and sales of SLM series metal 3D printing equipment and 3DP series casting specific 3D printing equipment, 3D printing processing services, and consumables. Especially in sand mold processing applications and rapid manufacturing services for complex shaped parts, the company has outstanding technical advantages and rich practical production application experience. The company's products and processing services are widely used in the rapid manufacturing field of industries such as automobile manufacturing, aerospace, mold manufacturing, casting industry, pump valve body, etc.

Partial product display

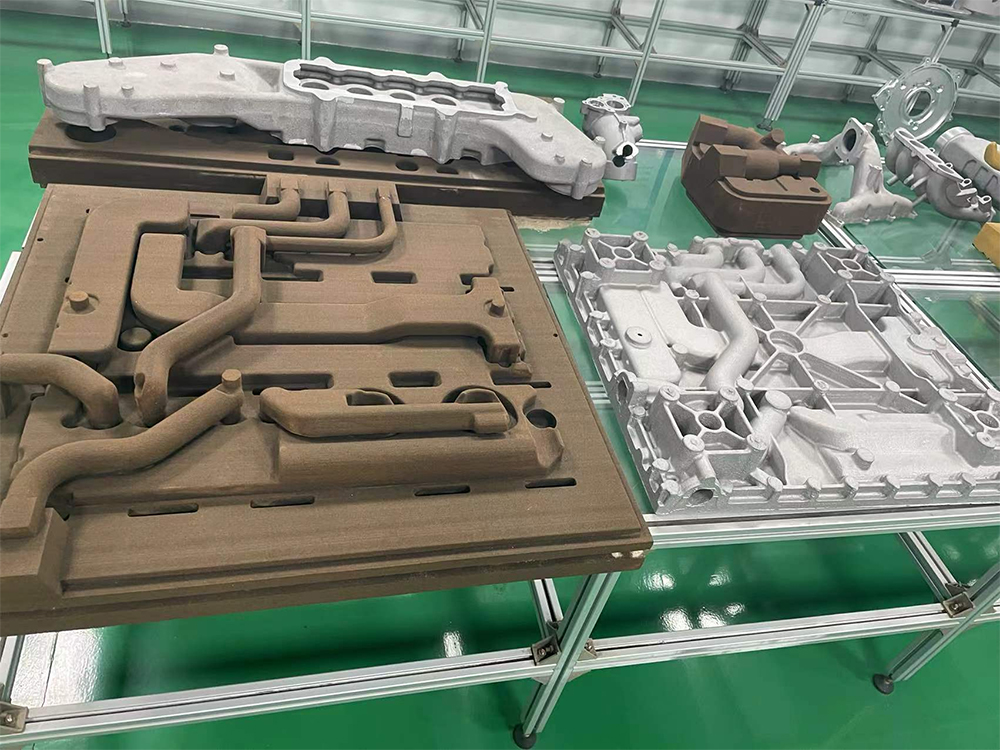

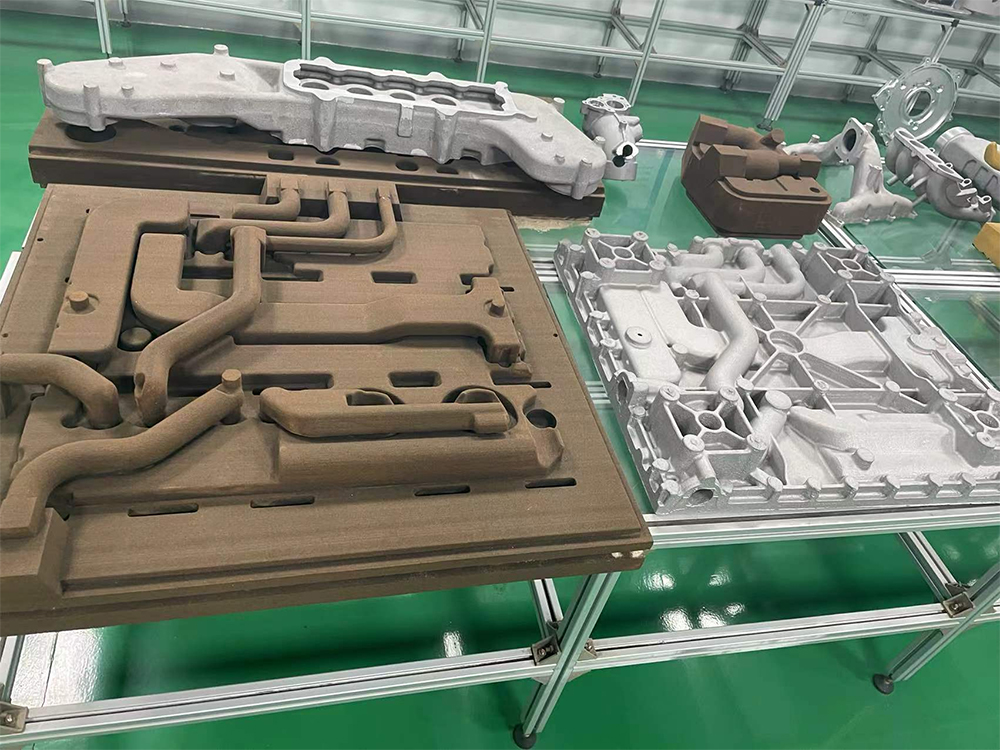

| 01 Ground Armor Lightweight Oil Pan |

The shell integrates 9 water and oil circuits, greatly increasing the difficulty and time consumption of the process. 3D printing, on the other hand, can print and shape components that originally needed to be divided into several parts as a whole. Both the difficulty and time of the process have been greatly reduced.

|

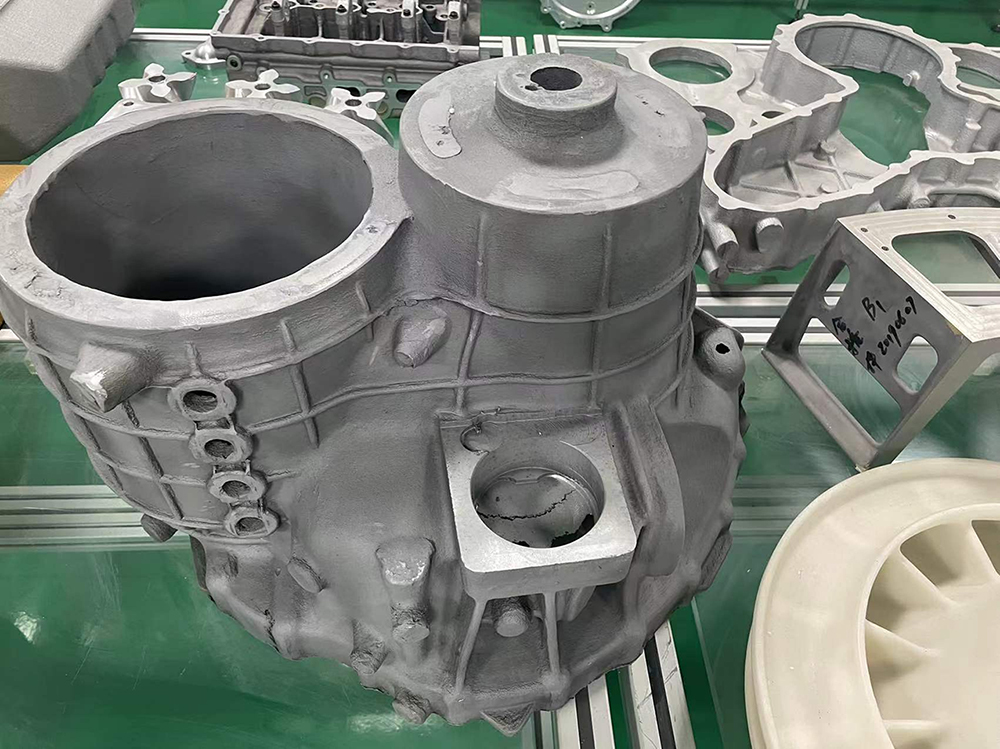

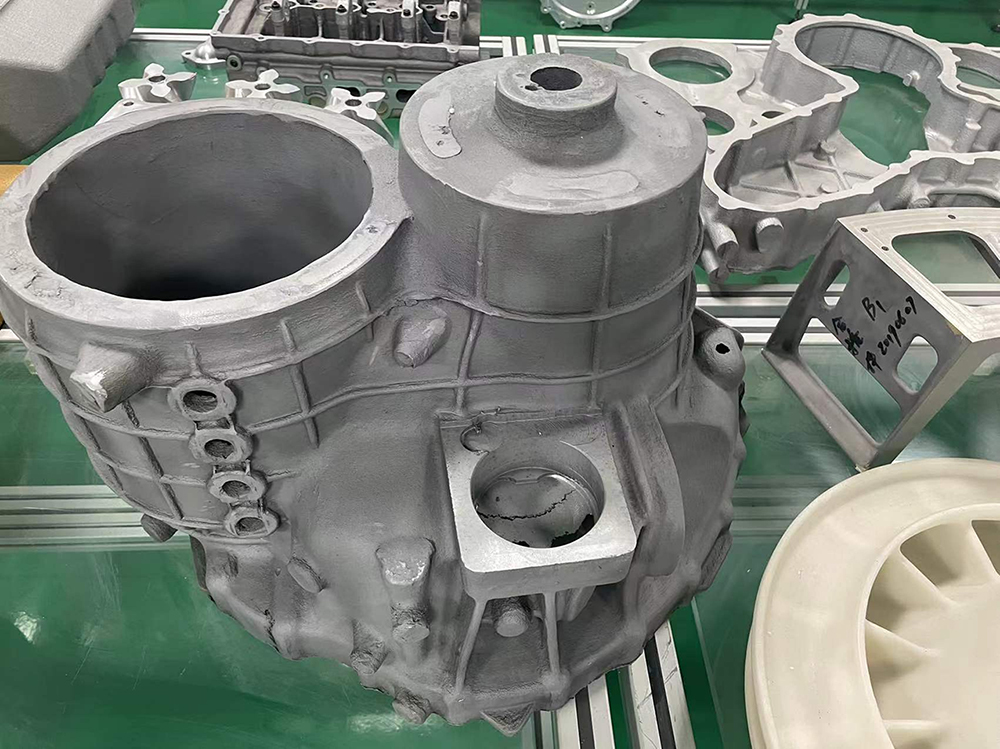

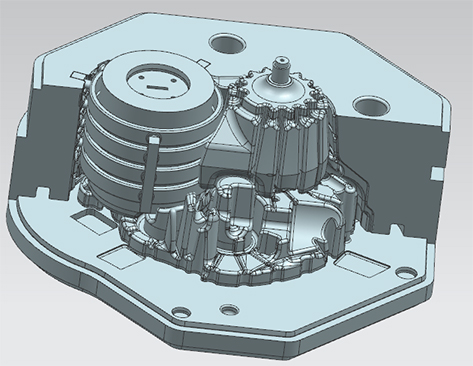

| 02 Tank V10 Lightweight Body |

The complex shaped air and flow channels in the cylinder block determine its position as the most difficult to manufacture among many engine components, and the corresponding development cost, development difficulty, and development cycle of the product are greatly increased. The use of 3D printing combined with casting greatly shortens the R&D cycle and reduces R&D costs for customers.

|

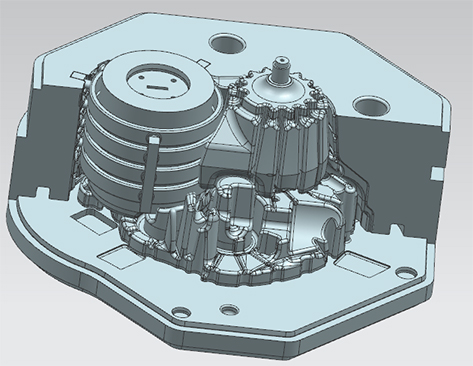

| 03 New energy extended range waterway integrated motor housing 1 |

A spiral water channel core integrated with the shell is also installed between the outer wall of the water-cooled integrated motor shell and the inner wall of the shell. The shell is equipped with a cooling liquid inlet and outlet connected to the spiral water channel core for cooling the motor. The development cost of a single water channel core mold using traditional technology is 60000 yuan, greatly increasing the development cost and cycle burden of the enterprise.

|